Aluminum Extrusion Finishes and Treatments

Why Finish Matters

Protection, appearance, and longevity

When it comes to aluminum extrusions, finishing isn’t just a final touch, it’s a crucial step that really shapes how well your aluminum systems will hold up over time. In a nutshell, the right finish acts as your first shield against everything from corrosion and everyday wear to the effects of the weather. It’s worth considering that a proper treatment helps maintain both the strength and the look of extruded aluminum, so your investment lasts longer and keeps looking sharp.

Even though aluminum is naturally resistant to rust thanks to its oxide layer, it’s important to know that it can still face challenges in tough environments. Think about places near the ocean where salt is in the air, industrial areas with chemical exposure, or regions with big swings between freezing and thawing. In these cases, the finish isn’t just about looks, it’s about making sure the structure stays safe and reliable. For example, if you’re using aluminum siding or aluminum panels in a humid or coastal area, you’ll likely need a more robust finish, not only to keep up with local building codes but also to follow best practices from organizations like the Aluminum Association.

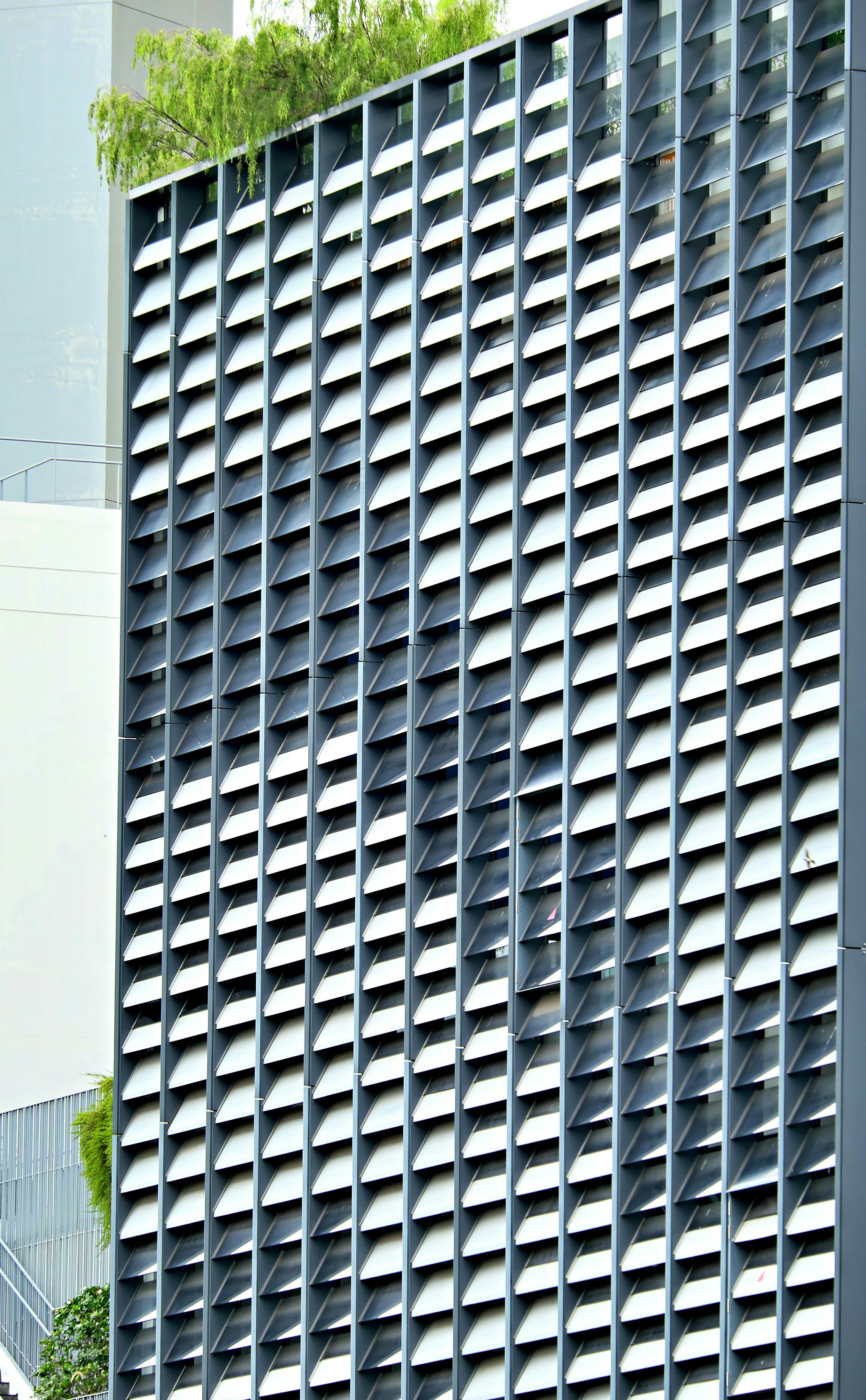

Choosing the right finish can really elevate the appearance and feel of aluminum siding, aluminum cladding, and aluminum panels. These finishes make aluminum products versatile for all kinds of architectural applications and help surfaces resist stains, scratches, and fading. By picking a finish that fits your needs, you’re making sure your extruded aluminum isn’t just strong, it’s also going to look good and last for years.

Something you should keep in mind is that certain finishes can also help you meet sustainability or green building goals. For example, if you’re aiming for LEED certification on a project, you might want to look at low-VOC coatings or finishes that make recycling easier and reduce the environmental impact of your project.

Exterior vs. interior performance needs

The requirements for aluminum extrusions can be quite different depending on whether they’re used outside or indoors. For exterior applications, like aluminum panels and cladding, there’s a need to stand up to weather, UV rays, and airborne pollutants. That means finishes need to focus on resisting corrosion, keeping their color, and needing as little maintenance as possible. On the other hand, indoor elements usually get to focus more on their appearance, feel, and texture, since they’re not exposed to the same harsh conditions.

For outdoor uses, finishes are often put through pretty tough testing, like accelerated weathering or salt spray tests (such as ASTM B117), to make sure they’ll keep their strength and look over time. Standards like these help ensure that products like aluminum cladding and panels will still look good and perform well, even after years out in the elements.

Knowing where your aluminum will be used helps you choose the right finish. For example, anodizing and powder coating are both popular for outdoor applications because they’re tough and hold up well against the weather. For interior uses, decorative mechanical finishes might be a better fit. Matching the finish to how and where you’ll use it is key to getting the most value and performance.

Inside, finishes can be picked to go with certain lighting, pair well with other materials, or create a specific feel. For instance, bead-blasted finishes are great if you want a soft, matte look in a modern office, while polished finishes might be the way to go in a retail space that needs a luxurious touch.

Aluminum Cladding Panels Engineered to Last

High-performance aluminum wall panels designed for durability, safety, and modern architectural applications.

Request a Quote →Anodizing

Clear, bronze, black; dye options

Anodizing is a go-to process for finishing aluminum. This electrochemical treatment makes the natural oxide layer on aluminum thicker, which boosts its corrosion resistance and gives you a consistent surface to work with. You can leave it clear (showing off the natural aluminum color), or go for dyed finishes, bronze and black are common, but there are plenty of custom options if you want something unique.

It’s worth noting that anodizing isn’t just about making aluminum last longer. It also gives you a lot of flexibility with how your aluminum looks. For instance, if you want the style of aged metal without the maintenance, bronze anodizing is a smart pick. Black anodizing is pretty popular in modern commercial spaces, delivering a sleek, even finish on things like curtain walls and window frames.

Color isn’t just about style, it can help tie in with branding or the overall design theme. Clear anodized finishes offer a modern, metallic look, while bronze and black give you deeper tones that work well in many different Extruded Aluminum designs.

Some manufacturers go even further, offering a whole palette of anodized colors such as champagne, gold, or custom shades. So, if you have a specific vision in mind, anodized aluminum can help you get there, whether it’s for function or aesthetics.

Seal quality, thickness, and corrosion resistance

The real effectiveness of anodizing comes down to two things: how well it’s sealed and how thick the oxide layer is.

Thicker coatings usually mean better protection against corrosion, which is especially important for exterior aluminum cladding and aluminum systems exposed to the elements.

ASTM International provides clear standards on what’s needed for anodized finishes, covering things like minimum thickness and sealing quality.

For example:

Class I anodizing, usually 0.7 mils or thicker, is recommended for outdoor architectural uses.

Class II (0.4 mils or more) is more common for interior projects.

Following these guidelines helps make sure your finish holds up as expected.

After anodizing, sealing is what locks in dyes and keeps out contaminants. A good seal keeps the color even and helps the aluminum resist weather, chemicals, and physical wear. If the sealing or thickness isn’t up to par, you could see fading, chalking, or even pitting, which isn’t just a cosmetic problem, it can affect the whole structure. That’s why reputable suppliers will often provide certifications or test results to prove they meet ASTM and other standards.

Wood-Grain & Decorative Films (Sublimation)

Species looks and pattern realism

If you want the look of wood without the hassle, wood-grain and decorative film finishes are something you should keep in mind. These are applied through sublimation, a process where detailed patterns are transferred onto aluminum using heat and pressure. The result is aluminum panels and siding that can look almost identical to real wood or other materials. Over the years, the realism has gotten impressive, you can find patterns that mimic everything from oak and cherry to walnut and maple.

The process starts with a base coat of powder, then the aluminum gets wrapped in a printed film with your chosen pattern. Heat and pressure do the rest, embedding that pattern right into the finish. This approach gives architects and designers a lot of freedom to create the exact look they want, whether it’s for a home, a commercial building, or something in between.

These decorative finishes are great for projects where you want the warmth of wood but need the easy care and durability of aluminum. For example, a multifamily housing project might use wood-grain aluminum siding to get the look of real wood but avoid the usual upkeep. Or, a retail center might choose decorative aluminum panels for a welcoming, durable façade.

UV durability and maintenance

Something that sets these decorative films apart is how well they stand up to the sun. High-quality films are made to keep their color and pattern, even after years of UV exposure. That makes wood-grain aluminum siding and panels a solid choice for outdoor spaces where real wood would fade or break down over time.

Many of these films are tested to meet international standards for colorfastness and weather resistance, like those set by the American Architectural Manufacturers Association (AAMA 2604/2605). These certifications offer some peace of mind that your finish will look good and perform well for years.

Maintenance is another area where these finishes really shine:

No need to stain, paint, or seal them.

Simple cleaning with mild soap and water keeps them looking fresh.

They resist peeling, chipping, and insect damage.

This lower maintenance adds up to savings and less hassle for property owners and managers.

Mechanical Finishes

Brushed, polished, bead-blasted

Mechanical finishes change the surface of aluminum extrusions using physical methods like brushing, polishing, or bead-blasting.

Brushed finishes create a linear texture that cuts down on glare and highlights the natural grain.

Polished finishes give you a shiny, mirror-like effect.

Bead-blasted finishes deliver a smooth, matte look.

Each of these finishes brings its own style to the table. Brushed aluminum is popular in modern kitchens and commercial interiors for its subtle elegance, while polished aluminum is often used for trim, signage, or lighting where you want something reflective and eye-catching. Bead-blasted finishes are great for hiding minor surface flaws and diffusing light, making them useful for both decorative and practical components.

When you’re deciding which treatment to use, it’s important to think about the final look you want and how the aluminum system will be used. Brushed and bead-blasted finishes often show up on handrails, fixtures, and interior accents, while polished surfaces are chosen for places that call for a high-gloss finish.

The texture of the finish can also affect later steps. Some textures help coatings or films stick better, while others might need extra prep to get the best result.

Slip/abrasion considerations for high-touch areas

Mechanical finishes are especially useful in spots that get touched and used a lot, think door handles, railings, or busy entryways. The finish you pick can make a big difference in how slippery the surface is and how much fingerprints or scratches show.

Brushed finishes are good at hiding everyday wear, so they’re a smart pick for high-traffic areas.

Bead-blasted finishes have a grippy feel that helps prevent slipping.

When you’re deciding on a finish for these types of spaces, it’s important to balance looks with real-world function, including how easy it’ll be to keep clean and how well it stands up over time.

For example, in public transit stations or sports arenas, bead-blasted or brushed aluminum is often used for grab bars and guardrails because they offer better grip and don’t show wear as quickly. Polished finishes look impressive but can show fingerprints more, so they may need more frequent cleaning in busy areas.

It’s also worth considering powder coating as an option here. Powder coating gives you a tough, protective finish and lets you choose from a huge range of colors and textures, matte, glossy, or even textured. You can even get special formulas for scratch resistance or anti-graffiti needs.

Organizations like the Aluminum Association and ASTM International set the standards for finishing processes, helping ensure the aluminum products you end up with meet expectations for both looks and performance.

When you’re choosing finishes and treatments for aluminum extrusions, don’t worry if it feels a bit overwhelming. Looking at real-world examples and learning from common mistakes, like using an interior-grade finish for something that’s going outside, can help you avoid costly errors. Always weigh practical data on things like wear, corrosion resistance, and maintenance alongside your visual preferences, whether you’re working with siding, cladding, or architectural panels.

Talking with experienced suppliers and checking out case studies from similar projects can also make your decision easier, making sure your chosen aluminum finish fits your design goals and holds up the way you need it to.

Frequently Asked Questions

-

The best finish for outdoor aluminum is usually anodizing or powder coating, as both provide excellent protection against weather, UV rays, and corrosion. Always check if the finish meets ASTM International standards for your specific application.

-

Wood-grain aluminum finishes offer the look of real wood with much less maintenance. They resist fading, chipping, and insect damage, and don’t require painting or sealing like natural wood.

-

Not always. Exterior applications require finishes that can withstand harsh weather and UV exposure, while interior finishes can focus more on appearance and texture. Make sure to match the finish to the intended environment.

-

Most modern finishes, especially powder coatings and sublimated films, require minimal maintenance—just occasional cleaning with mild soap and water is usually enough.

-

You can refer to organizations like the Aluminum Association and ASTM International for detailed standards and best practices.