Maintenance and Protection of Extruded Aluminum Facades

Why Proper Maintenance Matters for Aluminum Facades

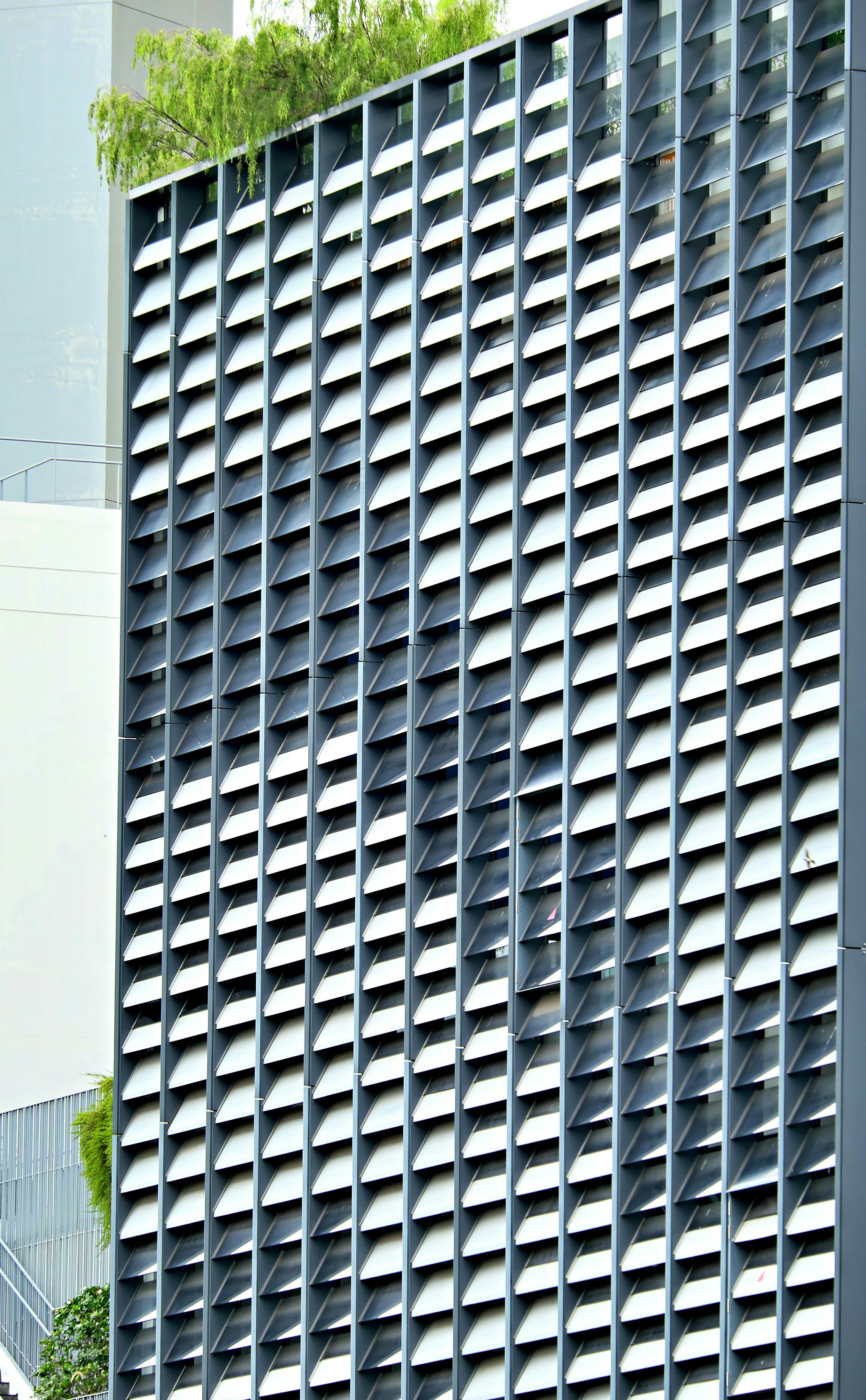

How aluminum reacts to environmental exposure

Aluminum has become a go-to material for modern building facades because it’s durable, lightweight, and naturally resists rust. Still, it’s important to know that when aluminum faces rain, sun, pollution, and changing temperatures, it can develop surface oxidation. This is actually a normal process that creates a protective layer, but keep in mind that exposure to things like acid rain, salty air near the coast, or industrial pollution can speed up staining or even corrosion if you skip regular upkeep. For folks with buildings close to highways, factories, or the ocean, these effects are even more noticeable since there’s a higher concentration of corrosive agents in the air. That’s why making time for regular cleaning and quick inspections is key, it helps maintain the protective qualities of your aluminum facade and keeps the whole building looking sharp. Plus, don’t forget that things like wind-blown debris or dirt buildup can scratch or discolor the surface, so staying on top of periodic care is essential for both how your building looks and how well it performs.

Benefits of proactive cleaning and inspection routines

Setting up a routine for cleaning and inspecting your aluminum cladding or panels brings plenty of benefits:

Regular care stops stubborn dirt, grime, and other residues from building up, which can wear down the finish or leave stains if ignored for too long.

Pollen, bird droppings, or city dust can leave marks that are tough to remove later.

Catching small problems early, like a bit of corrosion or sealant that’s coming loose, lets you fix them before they turn into bigger, more expensive headaches.

Staying proactive helps your aluminum systems last longer and keeps your property looking its best and holding its value.

Keeping up with maintenance helps you stay within the terms of manufacturer warranties and meet industry standards, so your exterior cladding and building facade keep performing well.

If you’re following guidelines from organizations like the American Architectural Manufacturers Association (AAMA) or your product’s manufacturer, you’re setting yourself up for success and making sure your warranty stays valid.

aPlank’s Approach to Long-Term Protection

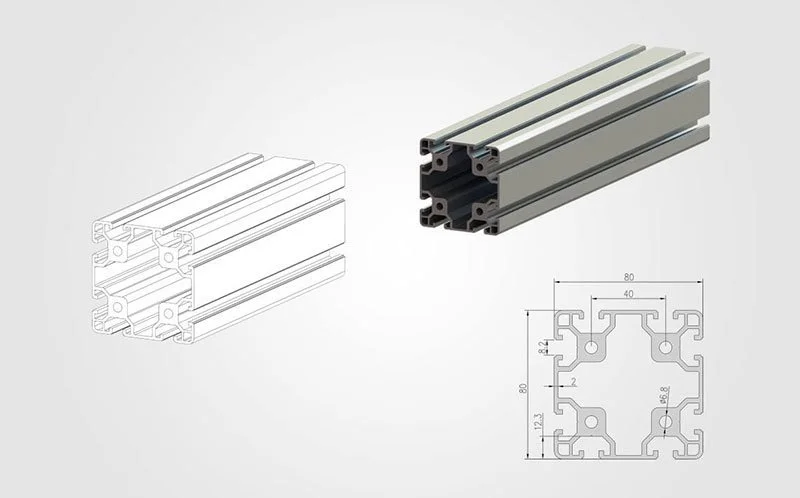

50-Year Extruded Aluminum Warranty: structural reliability

aPlank stands behind its Extruded Aluminum products with a 50-year warranty, which really speaks to the confidence they have in their aluminum extrusion and assembly process. This long-term promise is designed to give building owners and professionals real peace of mind. The warranty covers the main structural parts of aluminum siding, battens, and panels, so you know the framework will stay strong even after years of tough weather. This is especially important if you’re working on large commercial projects or high-rise buildings, where you need to count on structural integrity for decades. The fact that aPlank offers such extensive coverage shows their commitment to quality and industry best practices in manufacturing and assembly.

15-Year AAMA 2605 Finish Warranty: resistance to corrosion, cracking, and fading

When it comes to finishes, aPlank uses coatings that meet the demanding AAMA 2605 standard. In a nutshell, this is the gold standard for how well an architectural aluminum finish stands up to the elements, keeping its color and resisting damage. aPlank’s 15-year warranty means you’re protected against corrosion, cracking, and fading, helping your facade look great and stay protected. This kind of finish is a must-have in places with strong sun or harsh weather, where a weaker finish might wear out quickly, leading to extra maintenance costs. The AAMA 2605 certification shows that the finish has been put through tough weathering and durability tests, so you can trust it for demanding metal cladding projects.

The advantages of dye-sublimation HD woodgrain finishes

If you want the warmth of real wood but need the long-term benefits of metal cladding, dye-sublimation HD woodgrain finishes are worth considering. This process embeds a high-definition woodgrain pattern right into the aluminum surface, so you get a realistic wood look that doesn’t peel, flake, or fade like traditional painted or laminated options sometimes do. Since the woodgrain runs through the finish layer, it’s much more resistant to sun and weather. You get all the design flexibility and visual appeal of wood, but without the constant upkeep, no sealing, no repainting, and no worries about pests or warping. That’s a big plus for anyone who wants that classic look without the hassle.

Maintenance-free and UV-resistant surfaces

A lot of aPlank’s aluminum systems come with maintenance-free, UV-resistant surfaces, meaning you can forget about regular refinishing or repainting. These coatings are built to handle years of sunlight without fading or chalking, thanks to advanced technologies like fluoropolymer finishes that meet AAMA 2605 standards. So your building keeps its good looks and protective qualities with little effort, which is a big deal for places like schools, apartment buildings, or any property where long-term maintenance budgets matter. In the long run, these features help you save money and avoid unexpected repairs.

A Versatile Subframe for Exterior Wall Materials

Engineered to accommodate diverse exterior wall materials without compromising performance.

Start Your Project →Step-by-Step Guide to Maintaining Aluminum Facades

Recommended cleaning frequency and materials

Keeping your aluminum cladding clean is essential if you want it to last and keep looking good. For most buildings, cleaning twice a year is enough, but if your property is near the ocean or in a busy city, you might need to do it more often.

In coastal areas, salt can build up quickly, so it’s important to clean surfaces more frequently to avoid corrosion.

Use mild, non-abrasive detergents and a soft cloth or sponge, harsh chemicals or rough pads can actually damage the finish.

Most experts recommend pH-neutral soaps since acidic or alkaline cleaners can slowly wear away the protective coating.

Always rinse thoroughly with clean water to get rid of any leftover soap.

If you’re thinking about pressure washing, keep the setting low and always check the manufacturer’s guidelines first. Too much pressure or the wrong nozzle can strip the finish or push water into the joints.

For tough stains, you might need an approved solvent, but it’s smart to test a small spot first and follow the instructions closely.

Seasonal inspections and sealant checks

Doing seasonal inspections can help you catch problems before they get out of hand.

Look for things like fading, cracking, or spots where the sealant around joints is missing or damaged.

It’s especially important after storms or high winds, which can loosen sealant or blow debris into the panels.

Pay extra attention to where the panels meet other building materials or places where water tends to gather.

If you spot any issues, like a missing sealant or minor blemish, take care of them right away to keep your facade looking good and protected.

Keeping a maintenance log, just jotting down dates, what you checked, and any fixes, can really help with warranty claims and future planning.

In the end, staying on top of sealant checks is crucial to avoid water leaks that could lead to bigger structural or interior problems down the road.

Protecting Your Facade During Installation and Over Time

Proper subframing and thermal break installation (aFrame system)

How your aluminum panels and battens perform over time really comes down to how they’re installed. Using a well-engineered subframing system, like aPlank’s aFrame, helps keep everything aligned and stable. The aFrame system is designed to handle building movement, thermal expansion, and weight, which is key for making sure your facade lasts.

Adding thermal breaks to the subframing is another smart move, it helps save energy by stopping heat from moving through the exterior cladding, and it also cuts down on condensation and thermal bridging.

This is especially valuable in places with big temperature swings, since it helps keep indoor temperatures comfortable and lowers energy costs.

Following manufacturer and industry standards, like those from ASTM, will help you get the best results and keep your warranty in good standing.

Avoiding galvanic corrosion with compatible fasteners and sealants

Galvanic corrosion is something you might want to know about, it can happen when different metals touch and there’s moisture involved, which can harm your aluminum system. This is a bigger risk if you’re using stainless steel, copper, or other metals along with your aluminum panels or subframing.

Always use fasteners and sealants that are made to work with aluminum cladding and panels.

Sometimes you’ll need non-conductive coatings, gaskets, or insulators to keep metals from touching.

For example, stainless steel fasteners with the right barrier coating can help prevent corrosion.

Sticking with the manufacturer’s recommended accessories and sealants is the best way to make sure everything lasts and stays covered by warranty.

Ensuring ventilation and water drainage behind panels

A well-performing facade isn’t just about what you see on the outside, it’s also about what’s happening behind the panels. Good ventilation and drainage are essential to prevent moisture buildup, which can lead to corrosion or even mold.

Many systems use rainscreen designs that create a ventilated space behind the cladding, so water can drain and the wall can dry out.

This is especially important if your building is in a rainy or humid climate.

Make it a habit to check that drainage paths aren’t blocked and that ventilation isn’t covered up by insulation or sealant.

These steps go a long way in keeping your metal cladding strong and looking its best. Plus, a good drainage design can help prevent stains or other issues caused by trapped water behind the panels.

By following best practices and using advanced materials, you can make sure your extruded aluminum facades stay durable, attractive, and cost-effective for years to come. Keeping up with maintenance and relying on manufacturer-backed systems and warranties helps property owners and managers get the most value out of their aluminum systems and building facades. If you want to dive deeper into aluminum extrusion, exterior cladding, or related products, don’t hesitate to check out the resources from aPlank or get in touch with the manufacturer for more detailed advice.