What Is Extruded Aluminum? Process and Main Applications

Quick Definition of Extruded Aluminum

Extruded aluminum is basically aluminum that’s been pushed through a specially shaped die to create a continuous profile with a uniform cross-section. In a nutshell, it’s a process that turns raw aluminum into practical shapes that you’ll find everywhere—from construction and transportation to manufacturing and beyond. What makes extruded aluminum stand out is its strength, versatility, and how easily it can be adapted for specific uses, especially when it comes to building envelopes, facades, and a variety of aluminum systems.

Something you should keep in mind is that extrusion allows manufacturers to make all sorts of shapes, from simple solid bars to more complex hollow profiles and even multi-chambered components. This flexibility means extruded aluminum is just as useful for structural projects as it is for decorative touches. Plus, the process is efficient and helps reduce material waste, while letting you design profiles that can include features like drainage, attachment points, or insulation—all in one piece.

The Aluminum Extrusion Process (Step by Step)

Billet selection and alloying

The whole process starts by choosing an aluminum billet, which is basically a cylindrical log of aluminum. The alloy you pick here is important because it determines the final strength, appearance, and durability of the product. The 6000 series alloys, especially 6061 and 6063, are popular choices because they strike a good balance between strength, corrosion resistance, and ease of extrusion. The Aluminum Association (AA) sets the standards for these alloys, so you can count on a certain level of quality, especially for architectural uses. Alloying elements like magnesium and silicon are added to tweak things like strength, surface finish, or resistance to corrosion, depending on what the project calls for.

It’s worth considering that picking the right alloy affects not just how strong the profile is, but also how easy it is to shape and how good it’ll look once finished. For example, 6063 is great for architectural profiles because it provides a smooth, attractive surface that works well with finishes like anodizing. On the other hand, 6061 is often used for structural parts that need to hold up under more stress. Sometimes, the choice of alloy is also influenced by specific regulations or project requirements, especially in public spaces where safety and long-term performance are key.

Heating, die design, and direct vs. indirect extrusion

After selecting the billet and cutting it to size, it’s preheated to somewhere between 800°F and 925°F. This makes the aluminum soft enough to work with but doesn’t melt it. The heated billet is loaded into an extrusion press, where it gets pushed through a steel die by hydraulic pressure.

The die is what gives the aluminum its final shape, so its design is crucial. It needs to match the required tolerances, complexity, and the intended use of the finished profile. There are two main types of extrusion:

Direct extrusion: The billet is pushed through a stationary die.

Indirect extrusion: The die moves toward the stationary billet, delivering a better surface finish and requiring less force—ideal for more precise or delicate profiles.

Die design can range from simple shapes (like circles or rectangles) to really complex ones with internal channels or interlocking features. The choice between direct and indirect extrusion depends on things like how many pieces you need, the quality of the surface, and how complicated the shape is. For high-precision architectural components, indirect extrusion is often the way to go. Today, manufacturers use computer modeling to fine-tune die designs, helping ensure quality and keep production running smoothly.

Quenching, stretching, aging, and temper

Once the aluminum comes out of the die, it’s cooled quickly—this is called quenching. Depending on the alloy and the desired properties, this can be done with air or water. Next, the profile is stretched to make it straight and to relieve any internal stresses, then cut to the required length.

After that, the aging process comes in. The extruded profiles are reheated at a controlled temperature to achieve the desired temper, like T5 or T6. This further boosts the material’s strength and durability. The final properties of the aluminum depend on the alloy, the temper, and the precision of each step along the way.

It’s important to know that quenching and aging are key to getting the mechanical properties you need for structural or facade applications. For instance:

T5 temper: Cooling from the extrusion temperature and then artificially aging the piece.

T6 temper: Solution heat treatment before aging.

These steps affect not just strength, but also workability and the final surface. If quenching or aging isn’t done right, you might end up with inconsistent hardness, which can impact how well the profile performs, especially under stress.

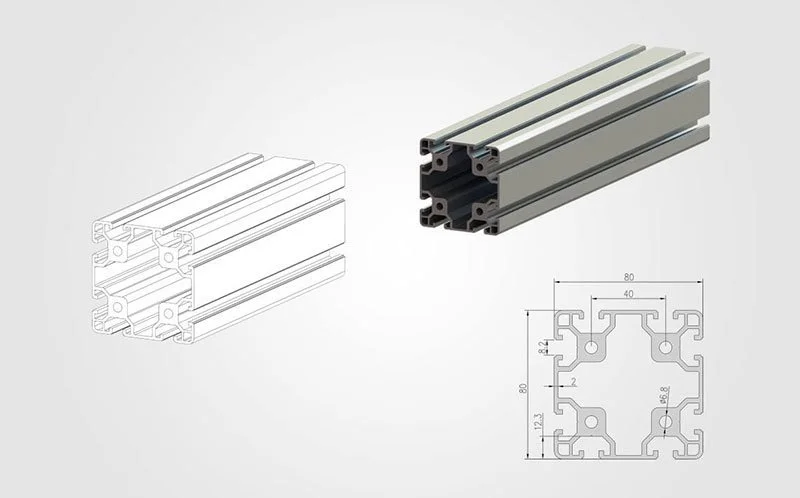

Tolerances, straightness, and profile complexity for cladding systems

For cladding systems, extruded aluminum profiles need to meet strict tolerances and be very straight to ensure everything fits and works the way it should. The complexity of the profile depends on both the die design and the extrusion process. You’ll find profiles with features like snap-fit connections, drainage channels, or built-in thermal breaks. Keeping these profiles straight, especially over long lengths, is essential, particularly for architectural uses like aluminum cladding and aluminum siding. Manufacturers stick to industry standards to guarantee dimensional accuracy and consistent quality.

In architectural projects, tight tolerances are essential because panels, trims, and subframes have to line up perfectly on site. Rainscreen systems, for example, might include built-in gaskets or pressure-equalization chambers to manage water and prevent leaks. Integrated thermal breaks—made by bonding insulating materials inside the extrusion—help cut down on energy loss and condensation. Quality control is a big deal here, with laser measurements and in-line inspections ensuring that everything meets project specs and industry codes.

Aluminum Cladding Subframe Engineered for Performance

aFrame is a thermally broken aluminum subframe designed to support modern rainscreen cladding systems efficiently.

Request a Quote →Advantages of Extruded Aluminum in Building Envelopes

Non-combustible solid aluminum; NFPA 285 “non-trigger” characteristics

One big advantage of using extruded aluminum in building envelopes is that it’s non-combustible. That means it won’t contribute to the spread of fire, and it meets some of the toughest fire safety standards out there. In facade systems, extruded aluminum profiles are often included in assemblies that don’t trigger the requirements of NFPA 285, which is a key fire test for exterior wall assemblies. For projects where fire resistance is a must, extruded aluminum is often the material of choice.

NFPA 285 is a widely used standard to check how exterior wall assemblies handle fire, especially when they contain combustible components. Since extruded aluminum is recognized as non-combustible by international building codes and ASTM E136, it makes the approval process easier for architects and specifiers. This is especially important in places like high-rise buildings, schools, and hospitals, where safety and code compliance are critical. Using solid aluminum profiles can also help when designing ventilated rainscreen systems that need to meet both performance and regulatory standards.

Lightweight strength, dimensional stability, and thermal movement control

Extruded aluminum is known for its high strength-to-weight ratio, which makes it a smart option when you need structural support without adding a lot of weight. This allows for larger spans and more flexible design choices in facade systems. Aluminum’s dimensional stability means the profiles hold their shape over time, no matter the weather. When extrusions are designed the right way, they can also handle thermal movement, so you won’t have to worry about issues caused by expansion or contraction as temperatures change.

Compared to heavier materials like steel or concrete, aluminum’s lighter weight can ease the load on building structures and foundations, which may save on construction costs. Its stability means you won’t see warping or twisting—something that’s important for keeping cladding panels looking and working their best over the years. Design details like slotted holes or flexible joints are often included to let the material expand and contract as needed, reducing the risk of buckling or joint problems when temperatures swing.

Durability, recyclability, and low lifecycle maintenance

Aluminum naturally resists corrosion, especially when it’s finished with anodizing or powder coating. This means you won’t need to worry about frequent maintenance, and the cladding or siding systems will last much longer. Another big plus is that aluminum is fully recyclable without any loss in quality, which supports sustainability goals in construction. Because you won’t have to deal with much maintenance over the years, building owners and operators can count on lower long-term costs.

Anodizing: Creates a tough, protective oxide layer that resists scratches and weathering.

Powder coating: Gives you a durable finish in just about any color or texture you want.

These treatments help aluminum stand up to tough conditions, whether that’s salty sea air, city pollution, or strong sunlight. Since recycled aluminum only takes a small fraction of the energy needed to make new metal, it’s a win for the environment too. Many green building programs, like LEED, recognize the use of recycled materials as a big plus for sustainability.

Main Applications of Extruded Aluminum

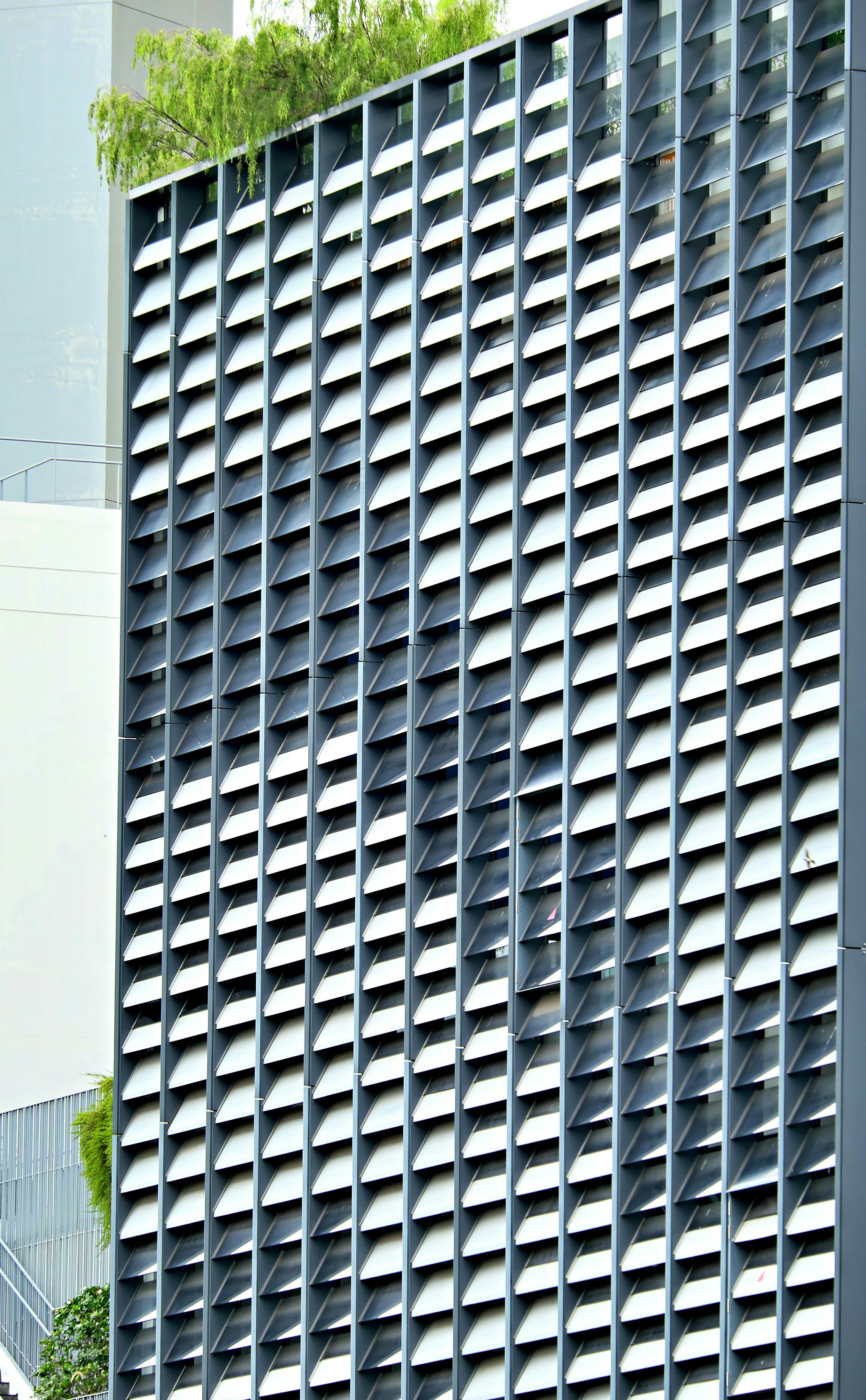

Architectural facades & rainscreen siding (wood-look aluminum planks)

Extruded aluminum is a favorite for architectural facades and rainscreen siding systems. A standout application is wood-look aluminum planks, which give you the look of real wood but with better durability, fire resistance, and almost no maintenance. These profiles are carefully engineered for a precise fit, reliable weather resistance, and strong visual appeal, making them a great fit for both commercial and residential projects. If you’re curious about different aluminum siding options, take a look at aluminum siding.

Wood-look aluminum planks are made using advanced powder coating or sublimation methods that really capture the grain and color of real wood. Unlike natural wood, you don’t have to worry about these profiles warping, rotting, or needing regular staining. This is especially appealing for multifamily housing, schools, or retail spaces where you want that warm, inviting look but need something that lasts. Rainscreen systems with extruded aluminum are designed to let water drain and air ventilate behind the cladding, which helps prevent moisture issues and keeps the building envelope in good shape for years.

Horizontal vs. vertical orientation; panelization strategies

You can install extruded aluminum profiles horizontally or vertically, depending on the design goals.

Horizontal installation: Can make a building look wider or give it a sleek, modern vibe.

Vertical profiles: Create a sense of height and modernize the appearance.

Panelization strategies group profiles into modules or panels, which makes installation easier and helps ensure everything lines up. Good panelization also makes it simpler to manage thermal movement and include proper joint details.

Orientation isn’t just about looks—it can also affect water management and shading. Horizontal profiles might include features like overhangs or drip edges to send water away from the building, while vertical profiles can help water drain off quickly. Prefabricated panels let you do a lot of the work off-site, which can improve quality control and cut down on installation time and mistakes. These panels can also come with built-in insulation, vapor barriers, or attachment systems, making the whole construction process smoother and boosting overall building performance.

Soffits, ceilings, and accent bands

Extruded aluminum isn’t just for facades—it’s also a great choice for soffits, ceilings, and accent bands. In these spots, it delivers a clean, modern finish and can be customized in color, texture, or even with perforation patterns. Because aluminum is lightweight, it’s perfect for overhead installations, and its resistance to moisture and mold means it holds up well in areas that are exposed or only partly sheltered.

Perforated aluminum panels: Used in ceilings and soffits to improve acoustics, offer ventilation, or create interesting lighting effects.

Accent bands and trim profiles: Can be finished in contrasting colors to highlight certain features or separate different parts of a building.

Using extruded aluminum in these ways helps create integrated designs that work well and look great.

Subframing & adjustable attachment systems (thermally broken)

Extruded aluminum is the backbone for subframing and adjustable attachment systems, especially when thermal breaks are needed. These systems support cladding panels and help handle loads from wind, earthquakes, or building movement. Systems with thermal breaks use special extruded profiles that include insulating barriers, which helps reduce thermal bridging and boosts the energy efficiency of the building envelope. For more details about the range of aluminum systems, check out aluminum systems.

Thermal breaks: Usually made by inserting a non-conductive material, like polyamide, between two sections of the aluminum profile.

Adjustable attachment systems: Make it easier to align panels perfectly, even if the building’s structure isn’t flawless, and help create a flat, uniform look.

These systems are key for high-performance facades and curtain walls, where energy savings and airtight construction are priorities.

Trim, starters, corners, and connection profiles

Extruded aluminum is also used for trim pieces, starter strips, corner profiles, and connection elements. These parts make sure transitions between different sections of the facade, or between panels and other materials, are smooth and watertight. High-quality trims help prevent water leaks, allow for building movement, and finish off the cladding system for a polished appearance. You can find examples of innovative approaches in aluminum cladding.

Starter strips: Provide a solid base for siding or panels.

Corner profiles: Protect edges and provide crisp lines.

Connection profiles: Might include expansion joints, gaskets, or built-in fasteners so the building can move as needed while keeping out water.

Manufacturers often offer a wide range of standard and custom accessories to fit the unique needs of each project.

FAQs About Extruded Aluminum for Facades

-

It’s important to know that extruded aluminum is considered non-combustible, so it won’t catch fire or help a fire spread. When used as a solid profile in facade applications, extruded aluminum usually doesn’t trigger the requirements for NFPA 285 testing. Of course, if you’re using it alongside other materials, you’ll want to check the entire assembly for compliance, but solid aluminum profiles are known for their fire safety performance in exterior walls.

When extruded aluminum is combined with insulation or other cladding materials, it’s a good idea to confirm that the whole system meets NFPA 285 or other relevant fire codes. Many manufacturers can provide the documentation and test results you need for code approvals.

-

Most facade profiles are made from 6000 series alloys, especially 6063 and 6061. These are popular because they’re easy to extrude, strong, have a nice surface finish, and resist corrosion. The Aluminum Association sets the standards for these alloys, so you can trust their performance for architectural uses.

Sometimes, other alloys like 6005 or 6082 are chosen for extra strength or specific fabrication needs. The finishing method can also influence the alloy choice, as some alloys work better with anodizing or powder coating.

-

Extruded aluminum profiles are built to last, often going strong for several decades if they’re properly specified and installed. Finishes like anodizing and powder coating add a layer of protection against corrosion, UV rays, and wear. The actual lifespan of the finish depends on the environment and how much maintenance is done, but top-quality finishes can look great for 20 years or more with minimal upkeep.

If your building is in a coastal or industrial area with lots of salt or pollution, it’s smart to clean the surfaces now and then to keep them looking good and performing well. Many manufacturers offer warranties on architectural finishes that last anywhere from 10 to 30 years, which shows the confidence they have in their products.

-

There’s a huge variety of finishes and colors for extruded aluminum used outside. Anodizing gives you a tough, metallic look in different shades, while powder coating lets you choose almost any color, including metallics and wood-look options. These finishes not only protect the aluminum for years but also make it easy for designers to hit the exact look they want for modern facades and rainscreen systems.

If you need something extra tough, specialty finishes like fluoropolymer coatings (such as PVDF) are available for projects that demand excellent color retention and resistance to harsh weather. You can also pick textured or matte finishes to cut down on glare or get a specific visual effect. Thanks to this combination of design flexibility and reliable performance, extruded aluminum is a top pick for architects looking for both function and creative freedom in exterior cladding.