Advantages of Extruded Aluminum in Modern Construction

Lightweight Strength for Structural Efficiency

When it comes to modern construction, extruded aluminum really stands out for its impressive strength-to-weight ratio. In other words, you get a material that’s tough and reliable, but without the heavy burden that comes with steel or wood. This makes a big difference for projects where structural efficiency is a top concern. For example, using aluminum extrusion allows builders to create large open spaces and eye-catching facades without having to worry about adding too much weight to the structure. Plus, the lighter weight means it’s easier and more affordable to transport and handle on-site, which helps keep project costs in check.

It’s worth considering that this lighter material doesn’t just ease installation—it actually allows for lighter foundations, which can be a game changer on high-rise projects. That’s especially helpful in areas where seismic activity is a concern, since reducing the building’s weight helps lower the forces experienced during an earthquake. So, if you want to meet safety standards and stick to your budget, aluminum systems are an option you shouldn’t overlook.

Durability & Corrosion Resistance

One thing people appreciate about extruded aluminum is how well it holds up over time. Unlike steel, which can rust, or wood, which might warp or rot, aluminum naturally forms a protective oxide layer. This gives it strong resistance against moisture, chemicals, and other environmental challenges. In places with tough climates or lots of pollution, that’s a real benefit. So, if you’re thinking about using aluminum siding or aluminum cladding, it’s important to know that you’ll get a material that needs little maintenance and can last for decades.

Also, finishing processes like anodizing can make aluminum even more resistant by thickening that protective layer and giving you options for color or texture. This is especially useful in coastal areas, where salt in the air can quickly wear down other materials. And because it doesn’t absorb moisture, you don’t have to worry about problems like mold or insects that can sometimes plague wood or composite materials. All this means you’ll likely spend less on maintenance and replacements, supporting long-term sustainability goals for your project.

Design Flexibility & Precision

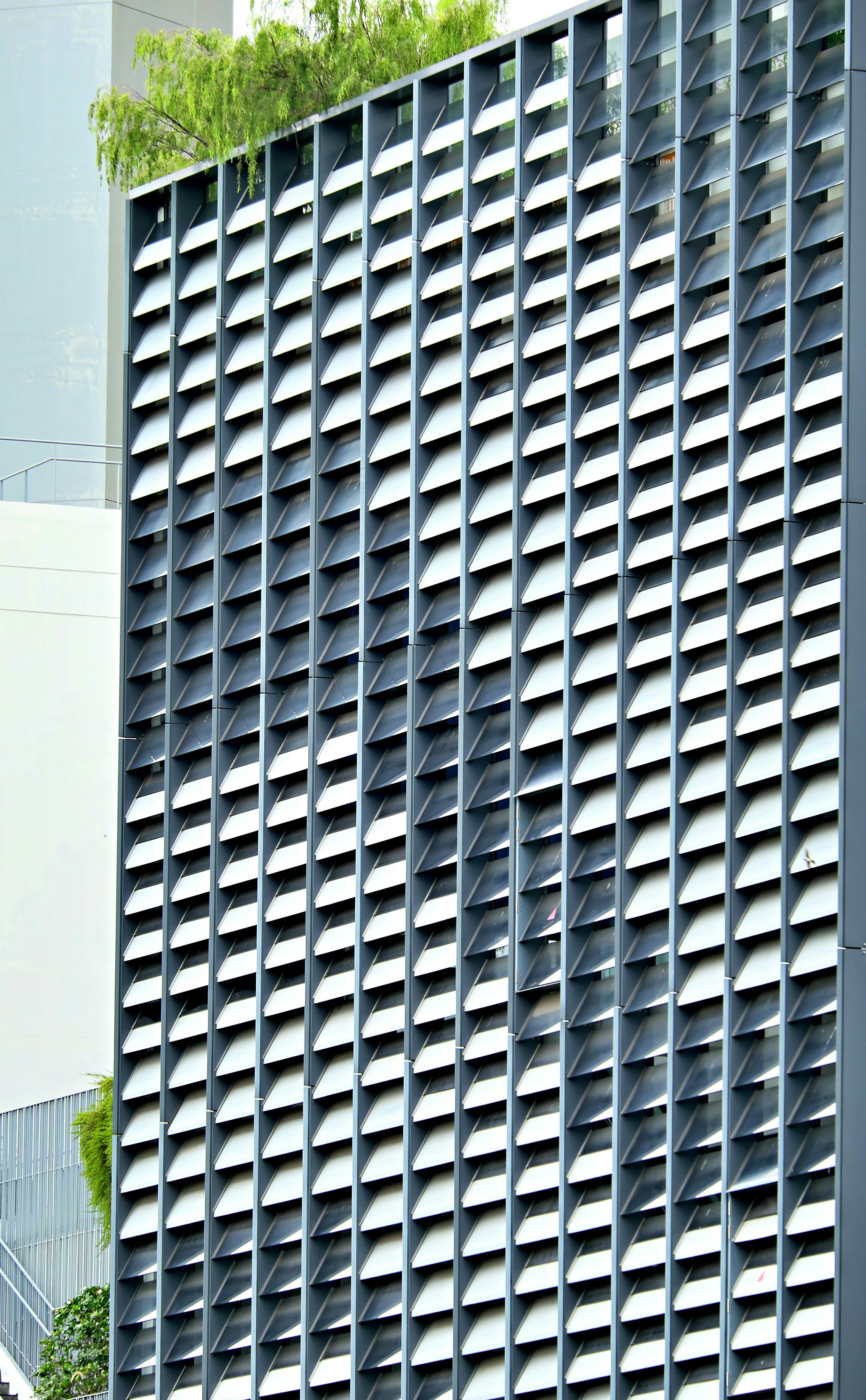

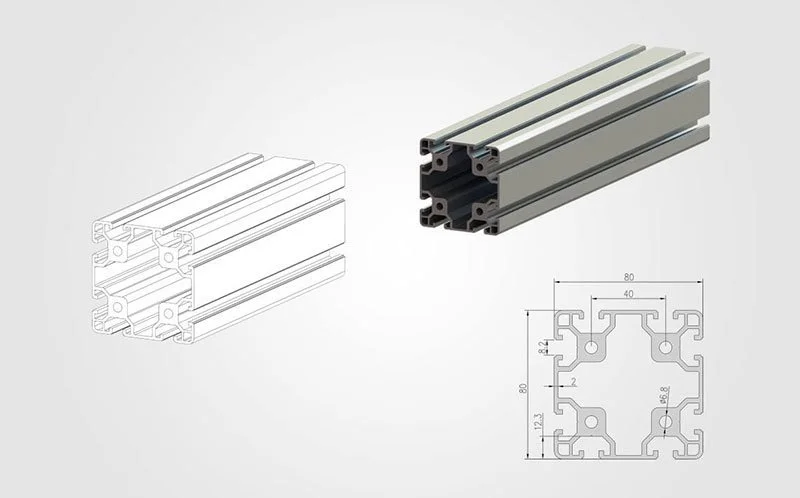

If you’re looking for versatility, extruded aluminum delivers. Its manufacturing process allows for the creation of complex shapes and custom profiles tailored to fit just about any architectural vision. This level of flexibility empowers architects and builders to design building envelopes, frameworks, or decorative details that might be difficult or expensive to achieve with other materials. Because extrusion technology offers such tight tolerances, you get consistent results—something that’s key for today’s construction standards.

For instance, if you need unique curtain wall systems, sunshades, or detailed trim, extruded aluminum can be shaped to your exact specifications. A good example is how architects can design special cross-sections for commercial facades that integrate directly with glass or insulation. In a nutshell, the precision of extrusion means you can even include features like gaskets or channels right in the profile, making installation smoother and the finished building more efficient.

Modular systems and rapid customization

Extruded aluminum can be quickly customized to fit prefabricated modules.

Manufacturers can adjust profiles to meet changing project needs, which is helpful for tight deadlines or design changes.

In modular hospitals or schools, frames can be made in standard sections and shipped ready to assemble.

For renovations or retrofits, modular aluminum systems allow for phased construction, making it easier to expand or update as needed.

Aluminum Battens for Modern Architectural Facades

Durable, lightweight, and weather-resistant aluminum battens designed for contemporary exterior cladding systems.

Request a Quote →Finishes That Perform

Another advantage of extruded aluminum is the variety of finishes available. You can choose from anodizing, powder coating, or specialized paints, all designed to boost both looks and durability. These finishes help protect the aluminum from fading, scratches, and general wear and tear, so it keeps its appearance and performance over time.

There’s also a wide selection of colors and textures, so you can match or contrast with other building materials for the exact look you want. Powder coating gives a tough, even finish that handles tough weather and frequent cleaning. Anodized surfaces can offer anything from a shiny metallic effect to a subtle matte finish. Beyond visual appeal, these treatments also help protect against graffiti, pollution, and other environmental factors that might otherwise damage the material.

UV, abrasion, and color retention

Finishes on extruded aluminum are designed to resist UV rays, abrasion, and fading.

High-quality finishes mean that aluminum siding and cladding maintain their color, reducing the need for repainting or early replacement.

UV-resistant coatings help prevent chalking and fading, especially in sunny regions.

Abrasion resistance is useful in busy areas or places exposed to wind-blown debris.

Many finishes meet strict standards set by the American Architectural Manufacturers Association (AAMA), making them a solid choice for LEED or green building projects.

Fire Safety & Code Considerations

When it comes to safety, especially fire safety, extruded aluminum is a material that checks a lot of boxes. Building codes are getting more strict about fire-resistance, and aluminum stands out because it doesn’t burn. That makes it a solid choice for architects and engineers who have to meet code requirements while keeping people safe.

The International Building Code (IBC) actually classifies solid aluminum as non-combustible, which means you can use it in places where fire safety is critical—like in high-rise buildings, schools, hospitals, or public spaces. Plus, using extruded aluminum can help you meet insurance requirements and lower your project’s risk profile.

Non-combustible solid aluminum

Solid aluminum extrusions won’t ignite or release toxic fumes in a fire.

These components hold their shape longer than many composites, providing more time for evacuation and firefighting.

No combustible fillers or adhesives, lowering risk for fire-rated assemblies and emergency exit routes.

Faster Installation & Lower Lifecycle Cost

One of the main reasons contractors like working with extruded aluminum is how easy it is to install and how much value it delivers in the long run. Its light weight means it’s easier to move and handle, and the precision of the manufacturing process ensures everything fits together just as it should. That translates into less labor, faster builds, and fewer headaches during installation.

Because you don’t need as many specialized workers, projects can often move along with smaller teams and finish more quickly. This is especially helpful in cities where keeping disruptions to a minimum is important. And don’t forget—lighter materials mean less need for heavy equipment, which can also make the job site safer.

Prefabrication and simplified attachment

Many extruded aluminum parts come pre-cut and ready to assemble.

Special attachment systems—like interlocking profiles or hidden fasteners—make installation faster and result in a cleaner look.

Factory quality control reduces the likelihood of defects.

Concealed fasteners help prevent tampering, which is important for schools and public buildings.

Repairability and recyclability

Extruded aluminum is easy to repair or replace if damaged, meaning less downtime and lower maintenance costs.

Aluminum is fully recyclable without losing quality, supporting sustainability and lifecycle cost goals.

High scrap value encourages recycling at the end of a building’s life.

Modular systems allow damaged parts to be swapped out without redoing the whole system.

Common Applications

You’ll find extruded aluminum in a wide range of construction projects, thanks to its strength, durability, and flexibility in design. It’s used for both the functional bones of a building and for decorative touches, so it works well in lots of different settings and architectural styles.

Beyond exterior envelopes, extruded aluminum is often chosen for:

Window and door frames

Skylights

Interior partitions

Handrails

Detailed trim work

It adapts easily to both new builds and renovations, offering solutions that can be tailored to whatever performance and design requirements you have in mind.

Facades, rainscreens, and soffits

Facades, rainscreens, and soffits are among the most popular uses for extruded aluminum. These parts of a building benefit not only from aluminum’s weather resistance and fire safety, but also from finishes that stand the test of time. With Extruded Aluminum, architects can create unique shapes and high-performance building envelopes that are tough enough for the elements and flexible enough for creative designs. The adaptability of aluminum cladding makes it easy to work with other materials and supports today’s trends in both commercial and residential construction. If you’re interested in learning more about the benefits of aluminum siding or how it plays a role in energy-efficient facades, it’s worth checking out resources on aluminum systems and exterior cladding for more details.

Rainscreen systems made from extruded aluminum help control moisture and airflow, which boosts both energy efficiency and durability. Aluminum soffits provide much-needed ventilation and a clean finish. For facades, the ability to create custom profiles lets you bring unique architectural visions to life, whether you’re aiming for a modern look or restoring a historic building. Using aluminum in these systems ensures you meet both the design style and performance standards expected by today’s architects, engineers, and building owners.

Frequently Asked Questions

-

Lightweight yet strong, making it easier to handle and reducing structural loads.

Highly durable and resistant to corrosion, even in harsh environments.

Offers design flexibility for custom profiles and complex shapes.

Meets strict fire safety and building code requirements.

Easy to install, repair, and recycle.

-

Yes, thanks to its natural oxide layer and optional finishes like anodizing, extruded aluminum resists corrosion and is ideal for coastal or humid climates.

-

Aluminum is fully recyclable without losing quality, has a high scrap value, and supports LEED and other green building certifications. Its durability also reduces the need for frequent replacement.

-

Absolutely. Its versatility and ease of customization make it suitable for both new builds and retrofit projects, including modular and phased construction.