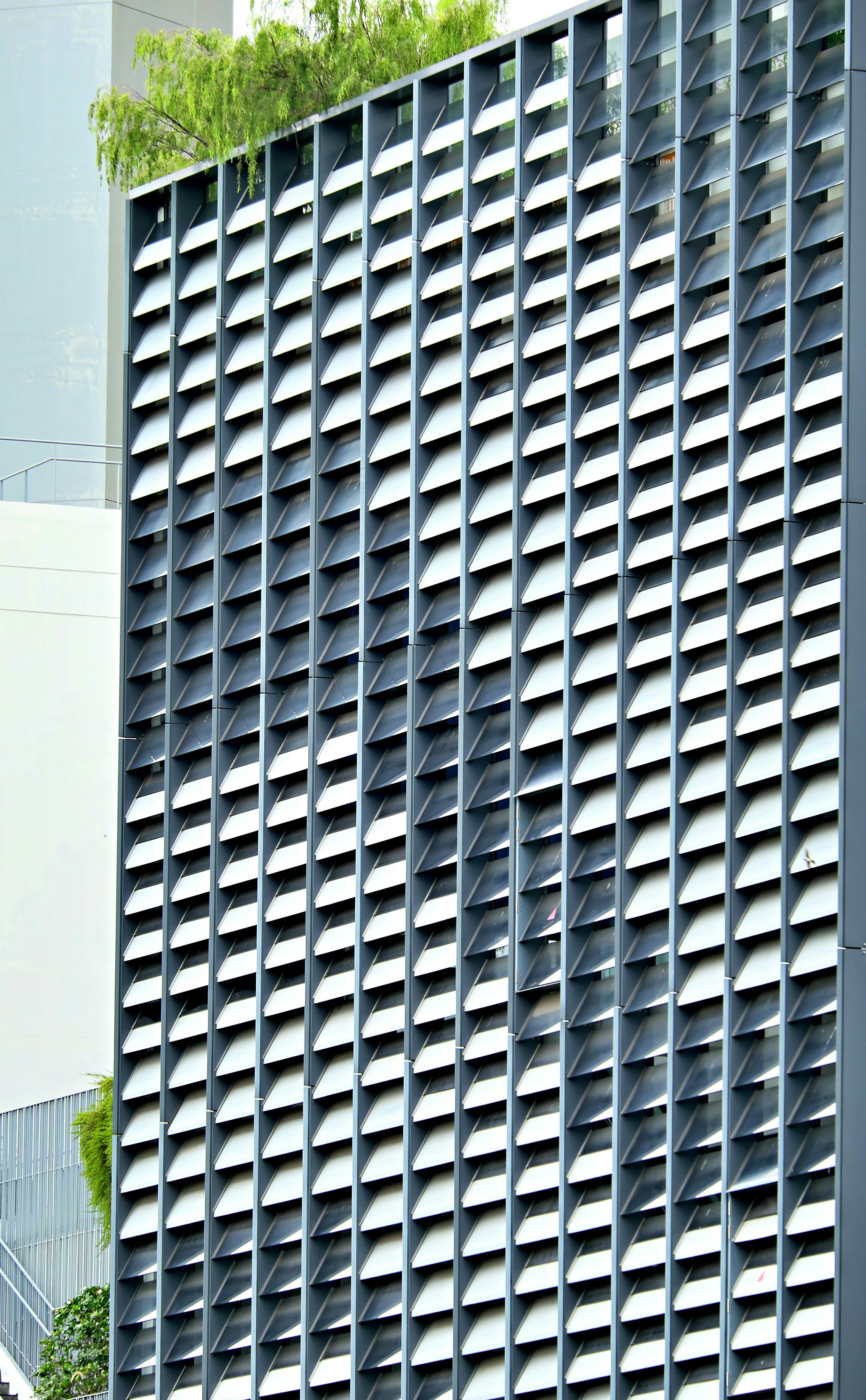

How to Choose the Right Aluminum Extrusion for Facades

Define Project Performance Goals

When you begin looking into the best aluminum extrusions for your building’s facade, it’s important to start by defining clear project performance goals. These goals are like your roadmap—they guide your material selection, design, and installation decisions from start to finish. Taking the time to really understand the unique needs of your building, the environment it’s in, and how it will be used helps ensure your final choice meets both immediate needs and long-term expectations. Setting these objectives early on helps everyone involved—from the owner to the installer—stay focused, whether we’re talking about the initial plans or the final touches.

Typically, these project performance goals cover:

Durability

Overall look and aesthetics

Compliance with safety standards

For example, if you’re working on a sleek office building downtown, you might care more about a modern appearance and strong thermal performance. On the other hand, a school or hospital may place higher value on impact resistance and easy maintenance. It’s worth considering input from everyone involved—architects, engineers, building owners, and facility managers—when you’re setting these goals, so that no important detail gets overlooked.

Climate, exposure, and building height

Something you should keep in mind is that local environmental conditions play a big role in choosing aluminum extrusions for facades. Factors like temperature swings, humidity, and how much rain or snow you get can speed up corrosion and affect how the material expands or contracts. Aluminum naturally forms an oxide layer that helps protect it, but if your project is near the coast with salty air, or in a city with lots of pollution, that protection can wear down faster. In these cases, it’s a good idea to look for extrusions made from alloys that resist corrosion or to add protective surface treatments.

Building height is another key detail. The taller your structure, the more it’s exposed to wind and pressure differences. Facade systems on high-rises, for example, need stronger extrusions with thicker walls and sturdy anchoring to handle those forces and keep everything safe and secure. The combination of your local climate and how exposed each side of the building is will help you decide on the right type of extrusion, wall thickness, and anchoring methods.

Also, don’t forget about solar exposure. South- and west-facing walls tend to get more sun, which can heat up the building and impact comfort and energy use. Choosing the right aluminum extrusion and finish can help reflect sunlight, reduce heat absorption, and keep your energy bills in check.

Fire, impact/wind, acoustic, and thermal targets

It’s important to know that your project’s performance goals should also address both regulatory and practical needs:

Fire resistance: Especially critical for taller or public buildings. The aluminum extrusion and its finish need to comply with fire safety codes and should not contribute to spreading flames. Many places require that facade systems pass tests like NFPA 285, and finishes often need to be non-combustible or only minimally combustible.

Impact and wind resistance: Building codes require that facades can handle impact and wind—this is even more important in areas prone to tornadoes or hurricanes. Systems have to pass standardized tests, such as ASTM E330 for structural performance and ASTM E1886/E1996 for impact resistance.

Acoustic performance: If your building is close to a busy road or airport, you’ll want to think about acoustic performance too, making sure the extrusion system can support sound-dampening features like gaskets or insulation.

Thermal targets: Aluminum extrusions should be compatible with thermal breaks and insulation to meet codes like the International Energy Conservation Code (IECC) and keep occupants comfortable.

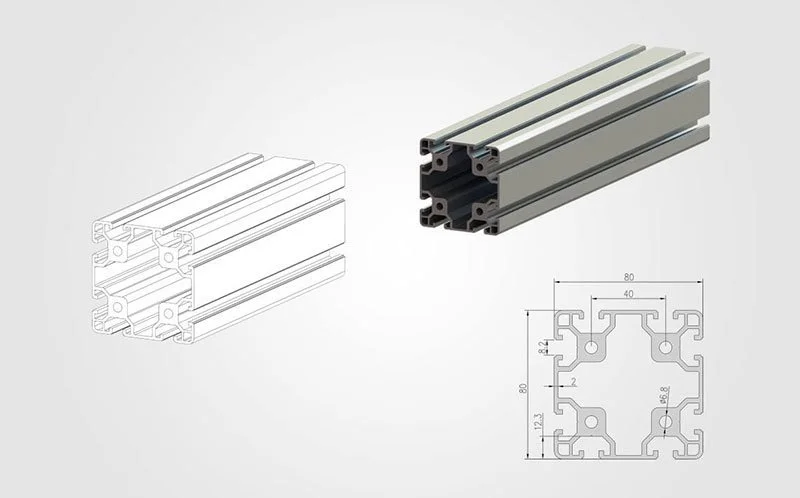

Select Alloy, Temper & Profile Geometry

After you’ve nailed down your project goals, your next step is to select the right alloy, temper, and profile geometry for your aluminum extrusion. Most facades use alloys from the 6000-series, such as 6061 and 6063. These offer a great mix of strength, corrosion resistance, and workability.

| Alloy | Strength | Surface Finish | Typical Use Cases |

|---|---|---|---|

| 6061 | Higher | Good | Structural components |

| 6063 | Moderate | Excellent | Visible facade elements |