Aluminum Facade Installation Best Practices for Architectural Projects

Why proper Aluminum Facade installation matters

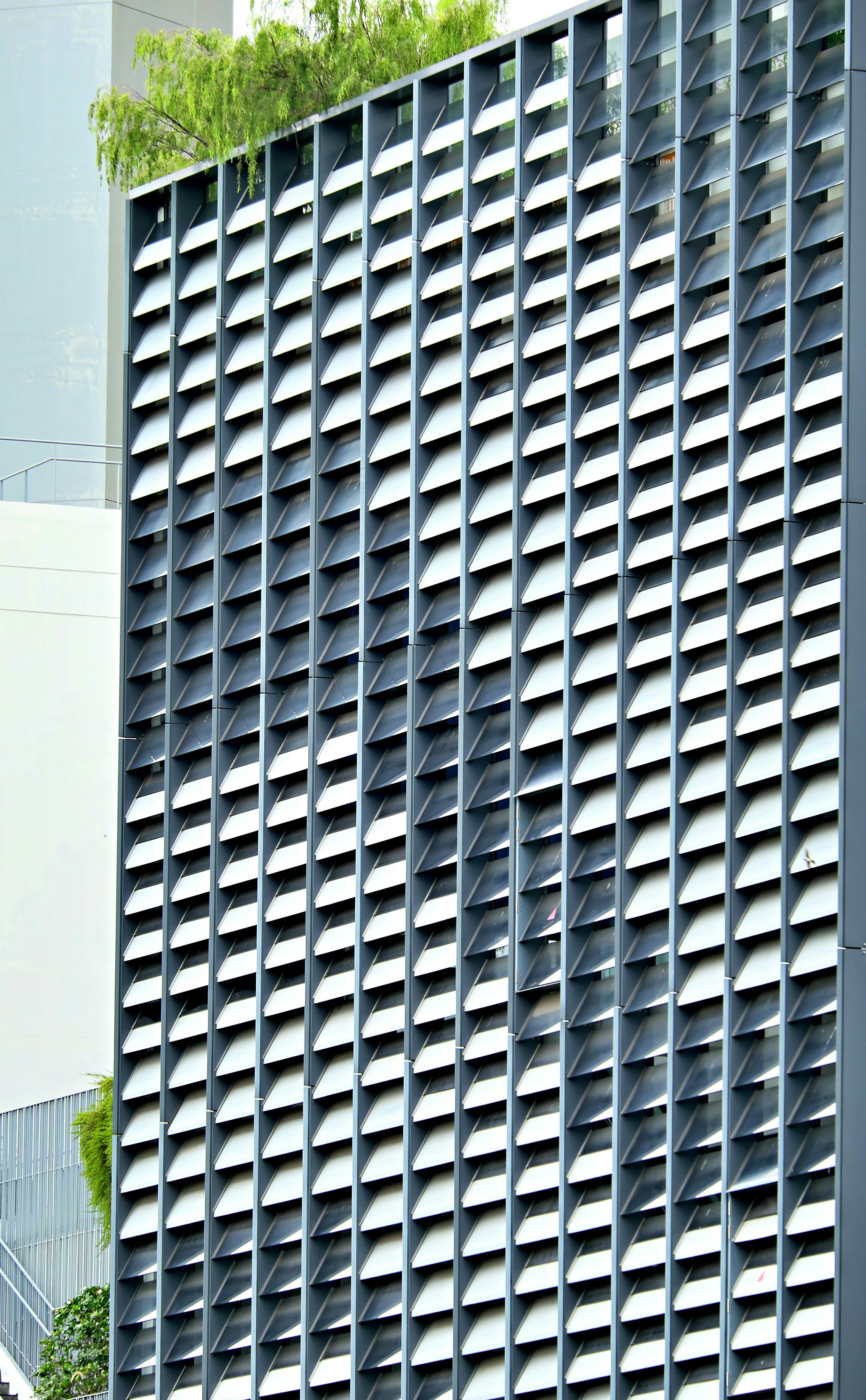

When it comes to any architectural project, installing an aluminum facade is not just about looks—it plays a huge role in how the building performs, how long it lasts, and the overall style it projects. If you get the installation right, you’ll see benefits like improved weather resistance, better thermal efficiency, and strong structural integrity over time. It’s worth considering that proper installation also helps you meet design expectations, stay in line with building codes, and support your energy efficiency targets.

Aluminum facades are especially appreciated for their resistance to corrosion and their ability to handle tough weather. They give commercial and residential buildings that clean, modern look. Since aluminum is lightweight, it’s easier to work with than other metal cladding options, which means less structural load and often a faster installation. In addition, choosing the right aluminum systems can help your project earn LEED certification credits, which is a plus if sustainability is important for your team or your clients.

But if the installation isn’t done correctly, you can run into real headaches—things like water leaks, poor insulation, panels that don’t line up, or even structural issues. These problems can drive up maintenance costs, shorten the lifespan of your building, and, in some cases, create safety risks. For instance, if joints aren’t sealed properly, moisture can sneak in and eventually lead to mold or damage inside the wall. Sticking with best practices helps you avoid these challenges and sets your project up for success.

Aluminum facade installation best practices for architectural projects

Getting aluminum facade installation right starts with thorough planning and choosing the right aluminum systems. Something you should keep in mind is the value of working with experienced professionals who understand the ins and outs of the building envelope and the unique properties of aluminum. Early collaboration between architects, engineers, and contractors makes sure the system you pick will meet your project goals and follow all the necessary codes.

During planning, it’s a good idea to evaluate the site’s exposure to wind, seismic conditions, and other environmental factors. This kind of assessment helps you decide which aluminum cladding system to use and what kind of structural support you’ll need. Always look for products that have been tested and meet local building code requirements, such as those from the International Building Code (IBC) and ASTM standards.

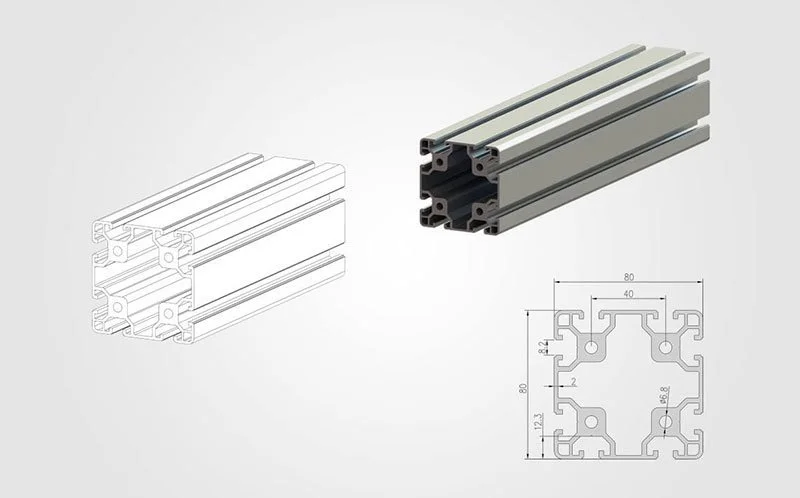

Choosing high-quality materials, like Extruded Aluminum components, is a must for a facade that’s both durable and visually appealing. Extruded Aluminum offers steady strength, accurate dimensions, and resists bending, which is crucial for keeping the facade in top shape over time. Make sure all your materials are compatible and line up with ASTM International standards for performance. For example, ASTM E330 covers how well the system stands up to pressure, while ASTM E283 and E331 deal with air leaks and water resistance. Before starting installation, review shop drawings, mockups, and manufacturer guidelines to make sure everything matches your design and technical needs.

A step-by-step approach—beginning with a dry fit or mockup—lets the team spot any issues early on. Paying close attention to the details as you go helps reduce mistakes and ensures a smooth, attractive finish. Keep in mind that regular inspections and careful documentation during installation are key for quality assurance and code compliance. On larger projects, you might even need third-party inspections or commissioning to confirm the system meets all requirements.

Cladding systems and subframing

Engineered aluminum subframing systems designed for fast installation, thermal performance, and long-term durability in modern cladding projects.

Talk to a specialist →Facade system installation guidelines and site preparation

For a successful aluminum cladding installation, thorough site preparation is essential. This means:

Checking all structural conditions

Double-checking measurements

Making sure every surface is clean, dry, and free of debris

If the substrate isn’t even, you’ll need to address those issues right away to avoid problems with alignment or extra stress on the panels. Planning ahead for logistics—like how you’ll store aluminum panels and protect them from damage—is also important. Store panels in a dry, sheltered place and handle them carefully to prevent scratches or dents.

Weather is another factor that can affect your installation timeline and the materials themselves. For example, extreme cold can make aluminum more brittle, while high heat can cause it to expand and make it tricky to keep everything lined up. You’ll want to monitor temperature, humidity, and wind so you can choose the best time to work. Sometimes, you may need to use temporary barriers or tents to protect the work area, especially if you’re using adhesives or sealants that need specific curing conditions.

Structural support and wall installation considerations

One of the most important steps in facade installation is designing and preparing the structural support system. The wall behind your panels has to be strong enough to handle the weight of the aluminum and resist wind loads, as called for by ASTM E330. Working closely with structural engineers helps make sure you’re using the right anchors, brackets, and fasteners. It’s a good practice to use stainless steel or other corrosion-resistant fasteners to avoid issues like galvanic corrosion that can show up over time.

When preparing the wall, remember to think about:

Moisture control

Vapor barriers

Insulation

For example, installing a continuous air and vapor barrier behind the aluminum cladding can help manage moisture and improve overall building performance. Using rain screen systems is also a smart move—they add a ventilated cavity that lets trapped moisture escape, which can really extend the life of your facade. Getting the alignment and level of the supporting structure just right is key for a clean, professional look. Tools like laser levels and string lines are great for making sure everything stays straight during installation.

Aluminum facade detailing and panel installation

When it comes to aluminum facades, the details make all the difference. Well-designed joints are important—they let the panels move as temperatures change and help prevent water from getting in. It’s smart to place expansion joints where they’ll absorb building movement or temperature swings. Also, think about how the panels line up with windows, doors, and other architectural features so the finished project looks intentional and polished.

Always follow the manufacturer’s instructions for installing panels, including the types of fasteners, how far apart to place them, and the sequence for putting the panels up. Some aluminum panels are designed for hidden fasteners, giving a clean, modern appearance, while others use exposed fasteners for a more industrial vibe. Using high-quality aluminum extrusion components helps keep the facade strong and long-lasting. Being precise during installation is crucial to avoid visible seams and uneven surfaces. Make sure to select sealants, gaskets, and backer rods that are compatible with aluminum and can stand up to the building’s environment for years to come.

Flat panel installation and aluminum metal panels

Installing flat aluminum panels takes patience and a steady hand. Here are some key steps:

Measure carefully and handle panels gently to prevent dents, scratches, or warping

Inspect each panel for defects before installation

Address any surface scratches or coating problems according to manufacturer’s recommendations

Use attachment systems that allow for thermal expansion and contraction, such as slotted holes, flexible clips, or proprietary mounting systems

Typically, aluminum metal panels are installed from the bottom up, making sure each row is properly aligned and fastened before moving on. This helps maintain level lines and ensures water drains the way it should. Depending on the panel type, you might need special hardware or clips—like for aluminum battens or composite panels—to provide extra support and allow for movement. Always follow the detailed installation instructions for each panel type. Sometimes, panels are custom-made to fit unique architectural details, so close communication between the fabricator and installer is key.

Common facade installation errors and how to avoid them

There are some common mistakes that can hurt the performance of an aluminum facade:

Panels that aren’t lined up correctly

Not using enough anchors

Forgetting to plan for thermal movement

Missing out on proper weatherproofing

For example, if you skip expansion joints or use rigid fasteners, the panels can buckle or the joints can fail as temperatures change. Using the wrong fasteners or not following the manufacturer’s instructions can lead to expensive repairs or even system failures.

To avoid these pitfalls:

Stick with reputable aluminum cladding systems

Check all technical documentation

Follow industry best practices

For instance, using ASTM E331 for water resistance testing or the IBC for fire performance requirements can help you meet safety and code standards. Regular training for your crew and keeping a close eye on the work helps keep quality high. Doing mockup installations and having pre-installation meetings can set clear expectations and help spot any issues early. Using quality control checklists, taking photos for documentation, and holding regular progress meetings are effective ways to keep the installation process on track.

By focusing on careful planning, choosing quality aluminum siding and aluminum panels, and sticking to proven best practices, you can achieve facades that are durable, beautiful, and high-performing for all kinds of building projects. Adding solutions like metal cladding and exterior cladding not only boosts the look of your project but also strengthens the building facade. Advanced aluminum systems, like insulated composite panels or ventilated rain screens, can further improve thermal performance and comfort for those inside. There are plenty of real-world examples—like high-rise offices or schools—that show how a well-installed aluminum facade brings lasting value, energy savings, and a standout architectural style.

Frequently Asked Questions

-

Durability, weather resistance, lightweight installation, and modern aesthetics. They also help with energy efficiency and can contribute to LEED certification.

-

Description text goes hereEvaluate environmental factors, building codes, and project goals. Always select tested products that meet ASTM International and IBC standards.

-

Rain screen systems create a ventilated cavity behind the panels, allowing moisture to escape and extending the life of the facade.

-

Work with experienced professionals, follow manufacturer guidelines, use quality materials, and implement regular quality control checks throughout the project.