Aluminum Facades for LEED Certified Sustainable Buildings

The Role of Aluminum Facades in Sustainable Building Design

Aluminum facades have become a go-to choice in modern building design, and it’s not hard to see why. Their versatility, durability, and aesthetic appeal make them stand out, especially when you’re aiming for sustainable construction. More and more, architects and construction teams are turning to aluminum systems when they want to create buildings that are both beautiful and environmentally responsible. One thing to keep in mind is how adaptable aluminum really is—it can be shaped and sized to fit just about any design, whether you’re working on curtain walls, rain screens, or something more custom.

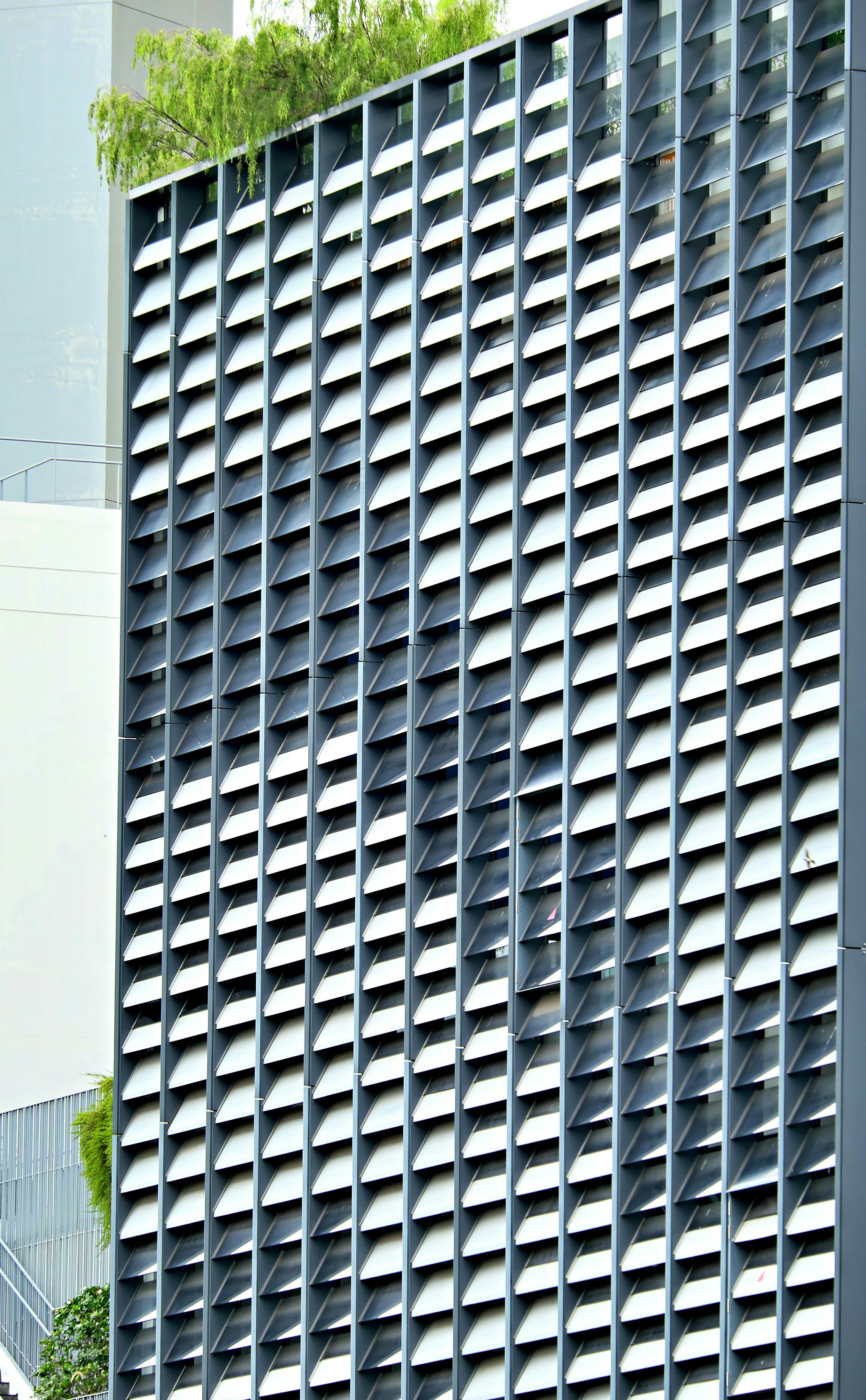

If you’re thinking about integrating architectural features like sunshades, louvers, or decorative aluminum battens, aluminum makes it easy to enhance your building’s energy performance and visual style. And don’t think it’s just for skyscrapers—aluminum systems are showing up in schools, hospitals, and homes where sustainability is a top priority. Plus, aluminum can be finished in a variety of textures and colors, giving architects the freedom to achieve unique looks without sacrificing environmental responsibility.

Another big plus is how long aluminum facades last. They naturally resist corrosion and weathering, which means you won’t have to worry much about maintenance as the years go by. This kind of durability really supports the long-term sustainability of your building’s exterior. And because aluminum is lightweight, it can help reduce the structural load on your building, which might even save you on transportation and installation energy.

It’s also worth considering that aluminum panels, compared to more traditional materials like masonry or stone, are much lighter. This can translate into savings on engineering and foundation costs. When aluminum is anodized or powder-coated, it keeps its good looks and strength for decades—even in tough climates or near the ocean. This kind of resilience adds real value over a building’s life and helps cut down on how often you have to replace or fix things.

Let’s not forget about energy efficiency. Aluminum facades can be specially engineered to boost thermal performance and work seamlessly with insulation systems, which helps reduce energy loss. When you combine aluminum cladding and aluminum panels with advanced glazing and insulation, you’re setting up your building for real energy savings and more comfortable interiors. All these features are right in line with sustainable design, promoting efficient use of resources and lower lifecycle costs.

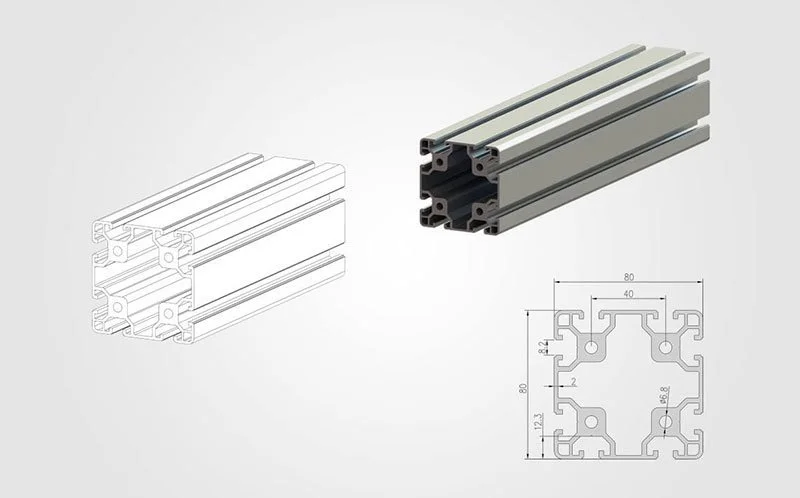

Here’s something you might want to know: adding thermal breaks to aluminum extrusion profiles can make a big difference in reducing heat transfer, which improves your building’s insulation. This is especially helpful in places with big temperature swings, where keeping things comfortable inside is key for saving energy. Aluminum systems can also accommodate triple glazing, built-in shading, and airtight seals, making them an excellent part of passive design strategies. All of these measures help reduce the building’s operational energy use and can give your project a boost when it comes to LEED energy modeling and meeting local codes.

How LEED Certification Evaluates Facade Materials

If you’re aiming for a green building, the Leadership in Energy and Environmental Design (LEED) rating system from the U.S. Green Building Council (USGBC) is the gold standard. LEED has clear criteria for evaluating the sustainability of building materials, including the facade. It looks at several categories:

Material and Resources (MR)

Energy and Atmosphere (EA)

Indoor Environmental Quality (IEQ)

Each of these categories offers credits for using environmentally responsible materials and systems. For example, under Material and Resources, you can earn credits for Building Product Disclosure and Optimization, which rewards you for picking products with verified environmental impacts and responsible sourcing. The Energy and Atmosphere category focuses on optimizing your building’s energy performance, and high-performing facade materials like aluminum cladding are a big help here. Indoor Environmental Quality considers how your material choices affect things like air quality, daylight, and thermal comfort—all of which benefit from a well-designed aluminum facade.

For materials such as aluminum siding and aluminum panels, LEED puts a spotlight on recycled content, regional sourcing, and the ability to reuse or recycle materials at the end of their life. It’s important to know that a lot of the aluminum used in construction already comes from recycled sources, which can help you score credits in the MR category for recycled content and responsible sourcing.

Manufacturers often provide Environmental Product Declarations (EPDs) and Health Product Declarations (HPDs) as proof of the recycled content and environmental impact of their aluminum systems. Choosing regionally sourced aluminum can also help reduce transportation emissions and support your local economy. The modular design of aluminum panels and aluminum battens makes it easier to disassemble and reuse them in future projects, which extends their lifecycle benefits.

Another factor LEED considers is life cycle assessment (LCA). This process looks at the environmental impact of facade materials from production to disposal. Aluminum stands out here because it can be recycled over and over without losing quality, which really helps shrink its environmental footprint. The LCA might also look at emissions from manufacturing and how the product affects your building’s energy performance.

A life cycle assessment reviews all the energy and resources used, plus the emissions produced, throughout a product’s life. Aluminum’s recyclability means that scrap from manufacturing or demolition can be turned into new products using much less energy than making aluminum from scratch. The Aluminum Association supports this closed-loop recycling system, which is one reason why aluminum cladding and metal cladding are great choices for sustainable design. Some manufacturers even participate in third-party recycling programs, making their environmental claims even more credible.

Aluminum systems are often chosen to meet or exceed LEED requirements for durability, energy efficiency, and safety. Having the right documentation—like EPDs and sourcing certifications—makes the LEED certification process much smoother.

Design teams can—and should—work closely with suppliers to get all the necessary paperwork for LEED submittals. This includes EPDs and certifications for low-emitting materials, coatings, and finishes. When you pick aluminum systems with verified performance and environmental attributes, you’re making it easier to move through the LEED review process and hit your certification targets.

Aluminum Facades and Green Building Certifications

Even though LEED is the top green building certification, there are other standards like WELL and BREEAM that also look at facade materials and their impact on sustainability and occupant health. Aluminum facades fit well with these standards, though LEED remains the most recognized here.

For example, the WELL Building Standard focuses on how buildings affect people’s health and well-being, considering factors like daylight, air quality, and thermal comfort. Aluminum systems can be designed to maximize daylight while minimizing glare, which helps with WELL credits for lighting and comfort. BREEAM, popular internationally, also looks at responsible material sourcing and lifecycle impact—areas where aluminum’s recycled content and durability really shine.

The Aluminum Association and various manufacturers provide documentation to back up LEED and other certifications, including technical datasheets for Extruded Aluminum and aluminum battens, as well as statements about recycled content and environmental impact.

These organizations often work with third-party certifiers to make sure their environmental reporting is transparent and accurate. Having access to technical datasheets, EPDs, and HPDs lets project teams compare aluminum systems to other facade materials, like fiber cement, terracotta, or stone, so you can make the best choice for your project’s sustainability goals.

Aluminum cladding and metal cladding systems can also be designed to boost daylight inside, reduce heat gain, and work with natural ventilation strategies—all of which help you earn credits not just for the materials you use, but for indoor environmental quality and innovation, too.

For instance, perforated aluminum panels can serve as shading devices that control solar gain while still letting in natural light, so you don’t have to rely as much on artificial lighting and your occupants stay comfortable. Adding operable features to aluminum facades can help with cross-ventilation, supporting passive cooling and better indoor air quality. Multifunctional design like this is becoming the standard in sustainable architecture.

If you’re looking for proof, there are plenty of real-world examples where aluminum facades have helped projects achieve high-performance certifications. Take educational campuses and government buildings that have earned LEED Platinum status by integrating aluminum siding and exterior cladding. These projects often see measurable reductions in energy use, maintenance costs, and embodied carbon, showing the practical value of aluminum in green construction.

Why Sustainable Aluminum Facades Support LEED Goals

Sustainable aluminum facades are a great match for LEED goals because they help boost energy efficiency, save resources, and support occupant well-being. The high recycled content in aluminum supports LEED’s Material and Resources credits, and its durability means less need for replacement or repair, which cuts down on waste throughout the building’s life.

Aluminum’s unique properties also help with LEED’s Innovation in Design credits. Manufacturers keep coming up with new finishes, coatings, and assembly methods to improve environmental performance. For example, low-VOC coatings and finishes on aluminum panels can make indoor environments healthier and help projects meet stricter air quality standards.

When it comes to energy performance, advanced aluminum panels and cladding systems can really improve a building’s profile, supporting credits under the Energy and Atmosphere category. These systems make it possible to include high-performance insulation and air barriers, which strengthen the building envelope.

By minimizing thermal bridging and improving airtightness, aluminum systems can significantly reduce heating and cooling needs. This is especially important for projects that want to go beyond basic code requirements or aim for net-zero energy. Using continuous insulation and advanced weatherproofing details in aluminum cladding assemblies helps you meet LEED’s focus on energy optimization.

Aluminum battens and aluminum extrusion products can be made with real precision, which cuts down on material waste and supports modular construction methods favored in sustainable projects. Many suppliers even offer take-back or recycling programs, further supporting circular economy principles.

Benefits of Modular Fabrication and Take-Back Programs:

Efficient use of materials

Off-site construction reduces waste and improves quality

Components are recycled at end-of-life, not sent to landfill

Choosing aluminum systems for your building facade is a way to show a real commitment to environmental responsibility and makes it easier to achieve LEED certification. The documentation and transparency from manufacturers, along with the consistent performance of aluminum facade solutions, help you earn the points you need.

Some manufacturers participate in industry initiatives like the Aluminum Stewardship Initiative (ASI) or Cradle to Cradle certification, which offer even more assurance about responsible sourcing and production. This kind of transparency is becoming more and more important for certifying bodies and clients who want to lower the environmental impact of their projects.

Aluminum Facades as an Eco-Friendly Facade Solution

Aluminum facades are an eco-friendly choice for building exteriors because they combine recycled content, recyclability, and strong performance. The material is widely available, and there’s a well-established recycling infrastructure to support its use.

Why Aluminum Is Eco-Friendly:

High recycling rate among construction materials

Significant portion of new aluminum from post-consumer and post-industrial sources

Robust network of recyclers and smelters for efficient reprocessing

Aluminum siding and cladding products come in a wide variety of finishes and colors, especially from suppliers who focus on aluminum panels. These choices give you a lot of freedom in design without sacrificing your sustainability goals.

Modern coating technologies like powder coating and anodizing deliver durable, low-maintenance surfaces that resist fading and corrosion. These finishes are usually low in VOCs, which is good news for indoor and outdoor air quality. Plus, the ability to specify custom colors and textures makes it easy for architects to create unique designs while still complying with green building standards.

If you’re careful in your selection, aluminum systems can help you avoid common mistakes, such as choosing materials with high embodied energy or limited options for end-of-life recycling. When you use aluminum as part of a holistic exterior cladding strategy, you’re helping to reduce your building’s environmental impact and making it more resilient and adaptable to changing green building standards.

For example, picking aluminum panels with verified recycled content and third-party certifications helps you steer clear of greenwashing and ensures your sustainability claims are solid. The durability and weather resistance of aluminum also mean you’ll need fewer repairs and replacements over time, which further cuts down your building’s lifecycle impact.

For architects, developers, and consultants weighing their options for sustainable building facades, aluminum stands out for its technical performance and alignment with leading certification standards. Partnering with suppliers who offer transparent information about aluminum panels, aluminum battens, and related products helps you make informed decisions and maximize the sustainability benefits of your building facade.

And finally, working with manufacturers who are active in industry initiatives—like the Aluminum Association’s sustainability programs—can give you extra confidence in your choice. By focusing on transparency, durability, and recyclability, your project can make a real contribution to achieving LEED and other green building certifications.