How climate and location affect the choice of Aluminum Facade systems

Why climate conditions matter in aluminum facade performance

When it comes to aluminum facade systems, climate conditions play a huge role in how well these materials perform and how long they last. It’s worth considering that factors like:

Humidity

Temperature swings

Rain

Wind

Exposure to salty air or pollution

can all impact the effectiveness of a building’s facade. Aluminum systems are popular because they’re versatile and look modern, but to really get the most out of them, you have to choose and install them with these environmental factors in mind.

Aluminum is known for standing up well to corrosion and being pretty durable overall. Still, how it holds up can change depending on the local climate. For instance, high humidity or areas close to the ocean can speed up corrosion if the right protective finishes aren’t used. In places where air pollution or acid rain is common, chemical reactions can wear down the surface of aluminum panels faster than you might expect. Extreme heat or cold affects how aluminum expands and contracts, which might cause issues like thermal bridging or make insulation less effective. If you’re in a region with strong winds—think about hurricane zones—the way the aluminum systems are attached and their structural strength should be carefully checked to avoid deformation or panels coming loose during storms. In a nutshell, understanding how climate and facade materials interact helps architects and builders make smart decisions, which can save money on maintenance down the road.

Aluminum facade systems by climate: key performance factors

Every climate zone brings its own set of challenges for aluminum facade systems. For example, in places where you get lots of freeze-thaw cycles, it’s important to use aluminum cladding that can handle expanding and contracting without warping or cracking. This really matters in northern or mountainous areas, where temperatures can swing dramatically between day and night, or from one season to the next.

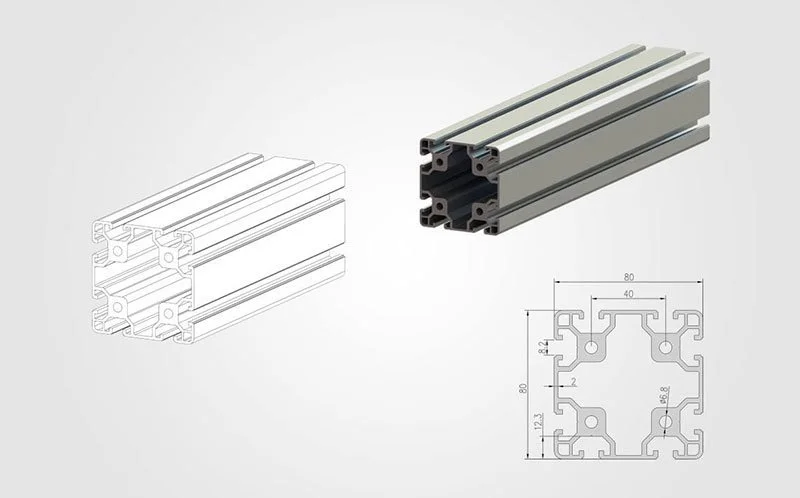

Something you should keep in mind is the concept of thermal bridging—basically, how heat moves through the facade material—which is a bigger issue in climates with big differences between indoor and outdoor temperatures. Systems that include thermal breaks, like thermally broken aluminum, are designed to interrupt heat flow and help with energy efficiency, as well as reduce condensation risk.

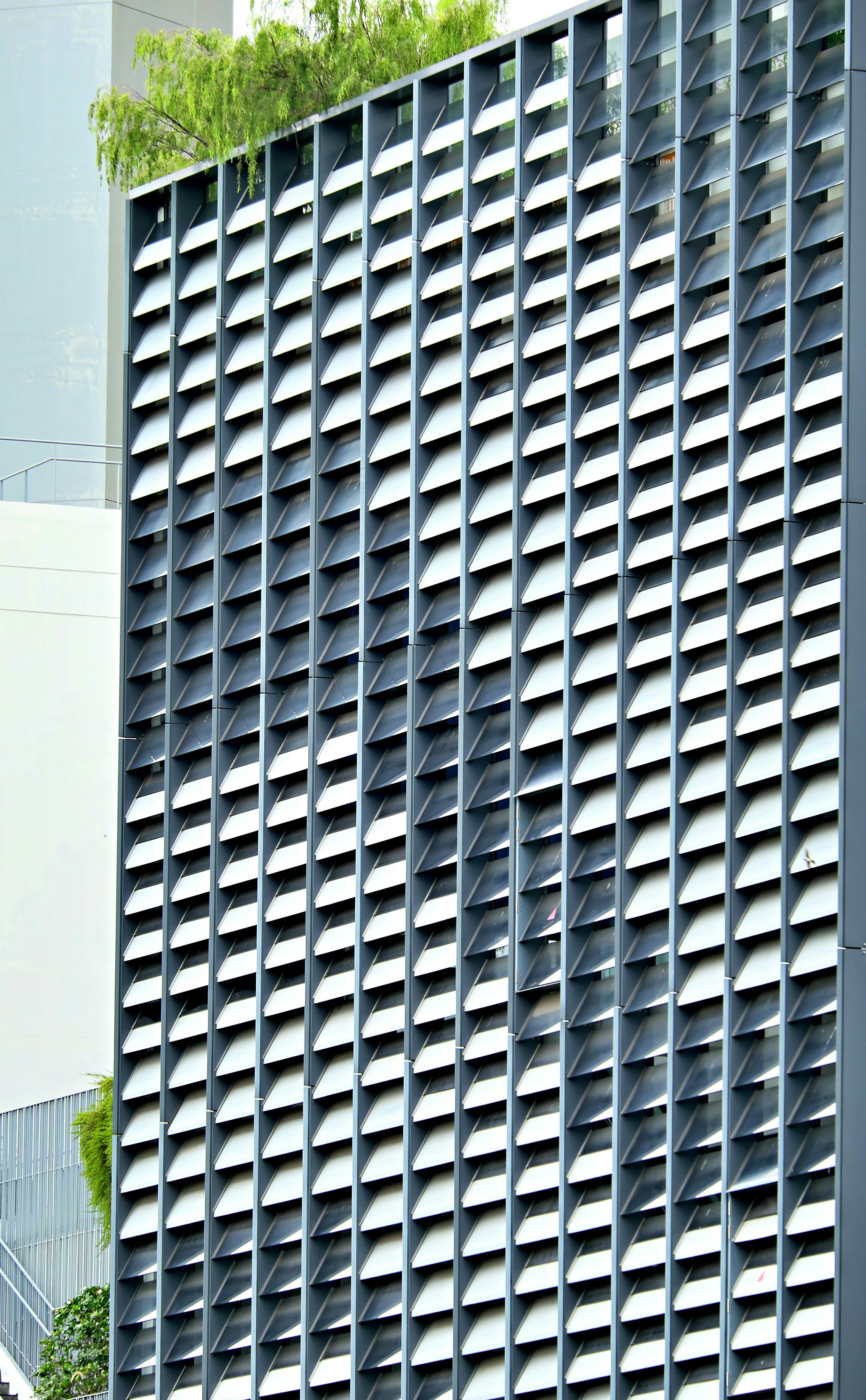

In hot and dry climates, solar radiation can make facade surfaces really hot. Choosing powder coating or other reflective finishes can help lower heat absorption, keeping interiors more comfortable. Lighter colors or coatings with a high Solar Reflectance Index (SRI) can also help reduce heat gain. On the other hand, if you’re dealing with areas that get a lot of rain or are very humid, proper drainage and moisture management inside the facade assembly is key to stopping water from getting in and causing mold or corrosion. Features like weep holes, ventilated cavities, or rain screens can be really effective here.

It’s important to know that following standards, such as those from the American Architectural Manufacturers Association (AAMA), ensures that products like aluminum siding, aluminum panels, and related items meet minimum requirements for things like air and water infiltration, structural strength, and finish durability. For example, AAMA 2605 sets out rules for high-performance coatings on aluminum, which is especially relevant if your project is in a tough climate. Taking the time to look over technical data and guidelines for metal cladding systems is a step you shouldn’t skip. Working closely with manufacturers and checking third-party test reports can help confirm you’re choosing the right system for your area.

Aluminum facades in coastal and marine environments

If you’re working near the coast, you’ll face some unique challenges. The mix of high humidity, salty air, and strong winds can be tough on aluminum. Salt, in particular, can speed up corrosion if your protective coatings aren’t up to par. For these situations, it’s a smart move to use specialized powder coatings or anodized finishes that act as a barrier against both salt and moisture. Some professionals go with marine-grade aluminum alloys, like those in the 5000 series, because they’re better at resisting corrosion from chlorides.

When designing a building facade for marine locations, you also need to pay close attention to joints and fasteners:

All parts should be resistant to corrosion.

Stainless steel fasteners are a good pick since they help prevent galvanic corrosion, which can happen when different metals touch in the presence of moisture.

It’s also important that the aluminum extrusion and attachment systems are compatible for long-term durability.

Real-world experience shows that when coatings fail or the wrong metal combinations are used, panels can deteriorate quickly. For example, some buildings on the waterfront have had panels fail early because of the wrong fasteners or not sealing the edges properly.

Maintenance is another big concern in coastal areas:

Regular inspections and cleaning of aluminum battens, aluminum cladding, and exterior cladding surfaces help remove salt deposits, which keeps the facade looking good and lasting longer.

Maintenance schedules can be tailored according to how close the building is to the water and how often salty winds hit it.

Choosing systems that have been specifically tested for marine environments adds peace of mind.

Some manufacturers even offer warranties or certifications that their products pass salt spray tests and other durability checks.

Facade materials for extreme climates: heat, cold, and humidity

Extreme climates—whether they’re super hot, extremely cold, or very humid—bring their own challenges.

In hot climates, aluminum facades with light-colored or reflective finishes can help keep solar gain and thermal expansion in check. Well-designed aluminum systems can also limit heat transfer, which helps the building stay energy efficient. In desert areas, some architects recommend ventilated facade systems that create an air gap, cutting down on the amount of heat getting inside.

For cold climates, freeze-thaw cycles and condensation are real concerns. You’ll want systems with solid weatherproofing and effective thermal breaks. When installing aluminum panels or aluminum siding, paying close attention to sealing and insulation keeps moisture out and prevents ice from forming inside the assembly. Using closed-cell insulation and vapor barriers can boost performance even more.

If you’re in a high-humidity environment—think tropical or rainy temperate climates—the risk of mold, mildew, and corrosion goes up. Powder-coated or anodized finishes give extra protection to aluminum cladding, and using rain screens or ventilated assemblies helps control moisture in the building envelope.

In regions prone to storms or hurricanes, it’s worth considering impact-resistant aluminum panels and reinforced mounting systems to handle flying debris and strong winds. Local building codes may even require facades to meet minimum performance standards, often based on the AAMA or ASTM International guidelines.

Thermal and corrosion performance of aluminum facades

Thermal performance is one of the main things to think about when choosing aluminum facade systems. Reducing unwanted heat transfer through the building envelope can make a big difference in energy costs and comfort for those inside. Since aluminum conducts heat well, it’s common to see systems designed with insulation and thermal breaks to prevent thermal bridging. For example, curtain wall systems might use polyamide strips or other materials that don’t conduct heat to break up the flow.

Corrosion resistance is just as important, especially in places with a lot of moisture or pollution. Picking the right finish—like a high-quality powder coating or anodizing—can really extend the life of aluminum extrusion and panels by stopping oxidation and surface damage. Some projects go the extra mile with several layers of coatings or sealants. Following AAMA standards during both selection and installation ensures that your materials meet strict criteria for thermal and corrosion resistance. For larger or critical projects, third-party certification and on-site testing might even be required.

Looking at real case studies, you’ll find that well-designed aluminum cladding and metal cladding systems, when installed and maintained the right way, can handle tough conditions for decades. High-rise buildings in big cities, for example, have shown lasting performance with minimal maintenance—provided the right materials and installation practices were used from the start. Paying attention to details like fastener compatibility, joint sealing, and regular maintenance helps avoid common problems and keeps the facade looking and performing its best. Proactive inspection programs can catch early signs of coating or sealant issues, so repairs can be made before bigger problems develop.

Choosing the right aluminum facade system really comes down to understanding your local climate and environmental challenges, and being committed to quality materials and proper installation. By taking a climate-responsive approach and relying on proven industry standards, architects and builders can create aluminum systems that are durable, efficient, and attractive for all kinds of projects. Working with experienced facade consultants and trusted manufacturers adds another layer of support, making it easier to achieve great results—even in the toughest environments.

Frequently Asked Questions

-

Thermal bridging occurs when heat moves through a material that is more conductive than the surrounding insulation, such as aluminum. This can lead to energy loss and condensation issues. Using systems with thermal breaks helps minimize this effect.

-

Choose marine-grade alloys, apply high-quality powder coatings or anodized finishes, use corrosion-resistant fasteners, and schedule regular maintenance to remove salt deposits.

-

Yes, following AAMA standards and consulting with manufacturers about their testing and certifications ensures your system meets strict requirements for performance and durability.

-

Regular inspections, cleaning, and timely repairs of coatings or sealants are recommended, especially in harsh or coastal environments. Maintenance schedules may vary based on local conditions.